Table of Contents

Introduction

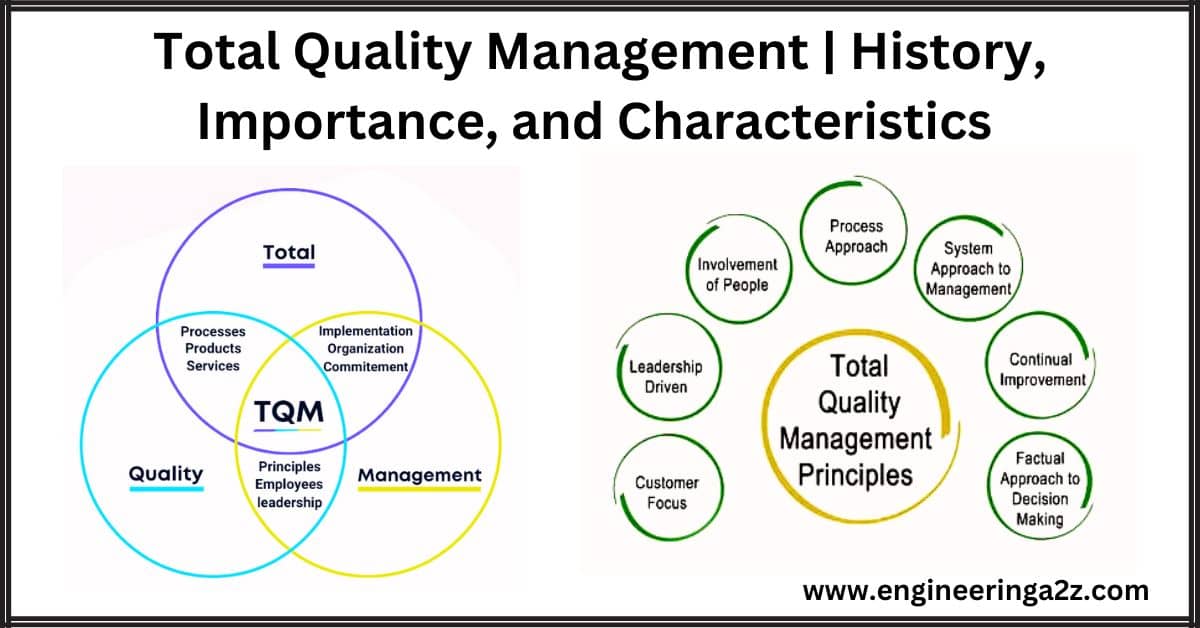

Total Quality Management (TQM) involves comprehensive endeavors across an organization to create a lasting environment where employees consistently enhance their capacity to deliver products and services promptly, which customers will highly value. The term “total” underscores the involvement of various departments beyond production, such as sales, marketing, accounting, finance, engineering, and design, in enhancing their processes. The term “management” highlights that top-level executives are responsible for proactively overseeing quality by investing in resources, training, staffing, and setting objectives.

Although there is no universally accepted method, TQM initiatives typically use established tools and techniques from quality control. TQM gained substantial attention in the late 1980s and early 1990s, but its prominence diminished as ISO 9000, Lean manufacturing, and Six Sigma gained more prominence.

History Of TQM

In the late 1970s and early 1980s, countries like the United States and Europe were having a hard time because Japan was making really good stuff that cost less. This caused them to lose in the economy. This was a big change because these countries were used to being the ones who made and sold lots of things.

So, the United States and others started thinking about why Japan was so good at making things. They looked at the ways to control the quality of products that had been developed over many years and how Japan used these ways successfully. This happened when the economies were struggling.

The name “total quality management” is not very clear where it came from. It might have been inspired by books about controlling quality, like Armand V. Feigenbaum’s book Total Quality Control and Kaoru Ishikawa’s book What Is Total Quality Control? These books were about making things really good. The name might have been first used by a department in the UK in 1983 to talk about making things better. Or it might have been first used by the US Navy in 1985 to talk about making things better too.

Importance Of TQM

Total Quality Management (TQM) is a way for companies to improve themselves and help their employees grow. When everyone in a company works together to make things better and always learns, it creates a culture that brings success to both customers and the company. TQM pays attention to making things good, which helps companies see where employees might need to improve. Then, the company can provide the right training, education, or guidance to help them get better.

TQM also promotes teamwork. It brings people from different parts of the company to work together and share what they know. This helps the company know more and lets them use their employees in different ways. In simple words, TQM is about making things better together and helping everyone learn and work together.

Characteristics Of TQM

- Customer Focus: TQM puts customers at the center. It’s all about making sure products and services meet customer needs and expectations.

- Continuous Improvement: TQM is about always looking for ways to make things better. This means finding and fixing problems to improve quality and efficiency.

- Employee Involvement: TQM involves everyone in the company, from top management to frontline workers. Employees contribute ideas and work together to improve processes.

- Process Orientation: TQM focuses on improving processes rather than just fixing individual problems. Better processes lead to better outcomes.

- Data-Driven Decision Making: TQM relies on data and facts to make decisions. Analyzing data helps identify areas for improvement.

- Management Support: Top management plays a crucial role in promoting TQM by providing resources, guidance, and demonstrating commitment.

- Teamwork and Collaboration: TQM encourages collaboration across different departments and teams to solve problems and achieve common goals.

- Prevention over Inspection: TQM focuses on preventing problems from happening in the first place, rather than relying solely on inspections to catch defects.

- Clear Communication: Open and effective communication is vital in TQM to share ideas, feedback, and progress updates.

Benefits Of TQM

TQM has these good things:

- Fewer Mistakes: TQM wants things to be done right the first time. This means fewer problems with the stuff a company makes. When things are made well from the start, there are less mistakes, so products don’t have to be fixed or taken back.

- Happy Customers: When things are made well and match what customers want, customers are happy. Happy customers talk about the good things, which brings in more customers. This helps the company grow and make more money.

- Less Spending: When there are fewer mistakes, the company doesn’t have to spend money on fixing them. This saves money on things like customer support and making things right. The company can keep more of the money they make.

- Strong Values: Companies that use TQM have strong values about making things good and always getting better. These values are in everything the company does, from hiring new people to making their products better.

Disadvantages Of TQM

TQM has some drawbacks too:

- Lots of Planning and Resources Needed: TQM requires a lot of careful planning and resources to work well. This means the company needs to spend a lot of time and money to make sure things change properly.

- Everyone in the Company Must Be on Board: For TQM to work, everyone in the company needs to be focused on making things better all the time. This includes people at different levels of management. If not everyone is on the same page, it won’t work well.

- Extra Costs: TQM can cost more money because of things like training, setting up new systems, and improving teams. These costs can add up.

- Takes Time: It might take a long time, even years, to see the full benefits of TQM. So, you need to be patient.

- Doing it Halfway Might Not Work: TQM needs a lot of effort. If a company only makes a few changes and doesn’t fully commit, it might not bring good results.

Frequently Asked Questions (FAQs)

-

What is TQM?

TQM improves products, involves everyone, and aims for constant betterment. Customer focus, teamwork, and efficient processes lead to quality, satisfied customers, and long-term success.

-

What are the characteristics of TQM?

1. Training and Development: TQM emphasizes the importance of training and developing employees’ skills to improve overall quality and performance.

2. Supplier Relationships: TQM involves working closely with suppliers to ensure the quality of incoming materials and components.

3. Long-Term Perspective: TQM aims for sustained success over time, rather than just short-term gains. It’s about building a culture of quality for the long haul. -

What is the full form of TQM?

The full form of TQM is Total Quality Management.

-

What is the principle of TQM?

Different versions of TQM exist, but some important parts stay the same. These are strong leadership, caring about quality, putting customers first, fixing mistakes, always getting better, and teaching employees well.

Read Also:

- Earth Leakage Circuit Breaker (ELCB) | Types, Working Principle, And Construction

- MCB : Miniature Circuit Breaker | Engineeringa2z

- Starting Methods of 3-Phase Induction Motor

- MHD | Magneto Hydro Dynamic Generation

- Stand Alone PV System | Schematics and its Components

- Difference Between A.C. and D.C.

Leave a Reply