Table of Contents

Introduction

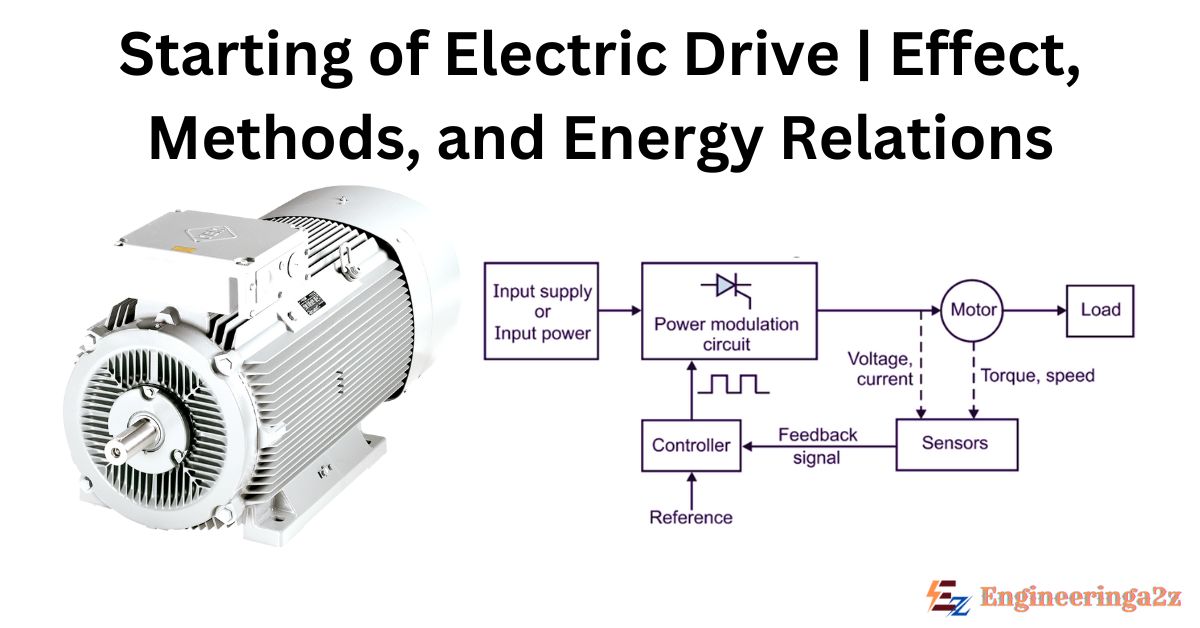

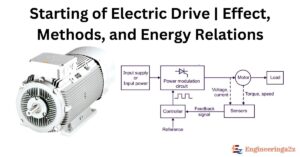

The most important processes associated with a controlled electrical drive are: (i) Starting (ii) Speed control or variation of speed of rotation (iii) Braking and (iv) Reversing the direction of rotation. As a rule, all these are transient processes that occur in a drive system.

Starting of an electrical drive involves a change in its state from rest to a steady state speed of rotation. The process of starting is the most important phenomenon in the entire operation of the drive. Control of the starting process essentially consists of controlling the acceleration of the driving motor and the latter is basically a problem of modifying the speed torque characteristics of the motor in such a way as to obtain the desired starting performance.

Effect of Starting on Power Supply, Motor and Load

While studying starting of electric drive systems, it is necessary to consider three factors: (i) effect of starting upon the power supply (ii) effect of starting upon the driving motor itself and (iii) effect of starting upon the connected mechanical load.

The supply network to which the motor is connected may affect the selection of the starting device from the following viewpoint. The excessive voltage drop due to the peak starting current may interfere with the supply in such a way that it cannot be tolerated by other equipment or other consumers connected to the same power supply network.

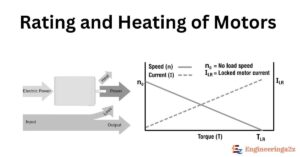

Since starting is associated with excessive currents, the effect of starting upon the motor itself must be carefully considered. The starting currents will add to the motor heating by an amount that depends upon their RMS values and upon the frequency of starting. In a de motor the limitation may be good commutation rather than heating, as de machines have a certain maximum limit for the current dictated by the commutation process.

The equipment connected to the driving motor may impose strict constraints upon the type of accelerating cycle and upon the maximum permissible acceleration. Discomfort to passengers in lifts and trains may very well set an upper limit to the rate of acceleration. Cranes, excavators and similar material handling equipment must be so equipped that the operator has precise control over the load, whether it be light or heavy. In case of loads, which exhibit stiction, the motor must develop sufficient torque to start the rotation, after which the torque must perhaps be reduced for limiting the acceleration to a safe value.

Methods of Starting Electric Motors

The different methods of starting of the various types of electric motors would have been dealt with in detail in a course on ‘Rotating electrical machines and hence, they have been just listed here for the sake of continuity of thought.

- Full voltage starting: This involves the application of full line voltage to the motor terminals. This is also called ‘direct-on-line-starting’. D.C. motors upto 2 kW and squirrel cage induction motors as well as certain small synchronous motors upto 4 or 5 kW are usually line-started.

- Reduced voltage starting: In order to avoid heavy starting current and the consequent voltage dip in the supply lines majority of motors started by applying a reduced voltage to their terminals and subsequently increasing it to its normal value.

The starting of a de motor is, often, accomplished by the addition of suitable external resistance in the armature circuit and the starting controller is arranged so that this resistance is short-circuited in steps as the motor comes upto speed.

Reduced voltage starting of induction motors is achieved by (i) stator resistance starting (ii) stator reactor starting (iii) star-delta starting and (iv) autotransformer starting.

The above methods apply equally well to the synchronous motors. With reduced voltage starting the transition to full voltage may be made either before or after synchronization although the former method is usually preferred. It may be noted that the torque at starting, in all the above methods, gets reduced.

- Increased torque starting: With a wound rotor induction motor, resistance can be added in the rotor circuit so as to decrease the starting current while increasing the starting torque, even, upto the value of maximum torque that can be developed by the motor.

- Starting by means of smooth variation of voltage or frequency: With ac- motor-de generator sets, de motors can be started by smooth variation of applied voltage and with variable frequency sources both induction and synchronous motors can be started by smooth variation of supply frequency, simultaneously varying proportionally the applied voltage to the motors.

Energy Relations During Starting

Certain useful expressions regarding the energy losses in a motor during periods of changing speed like tarting, braking and sudden changes in applied voltage, load etc. can be obtained as described below:

1. DC Shunt Motor

An expression of the form given below may be obtained for the energy lost in the armature of a dc shunt motor.

The voltage equation of the dc motor is

V = E + Ia Ra or Ia Ra = V – E

For the shunt motor,

Ia Ra = V – Kω

The above Eqn. separately excited motor also. The equation of motion on no load will be

TM = KIa = J . (aω) / (dt)

2. DC Series Motor

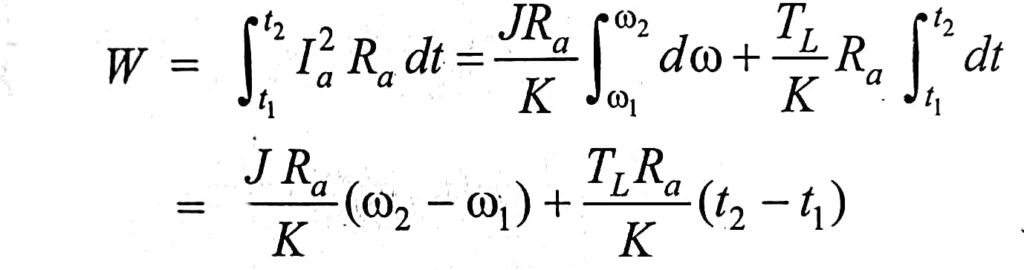

Since a dc series motor should not be started on no-load, let us assume a constant load torque TL to be present, while determining the energy loss during starting.

The equation of motion will be,

TM = KI2a = J . dω / dt + TL

Hence, the total energy dissipated, in the armature circuit resistance is given by the following expression,

Thus, the energy dissipated, speed changes from ω1 to ω2 is proportional to R alpha’ the armature circuit resistance, rather than independent of this quantity as in the case of a de shunt motor.

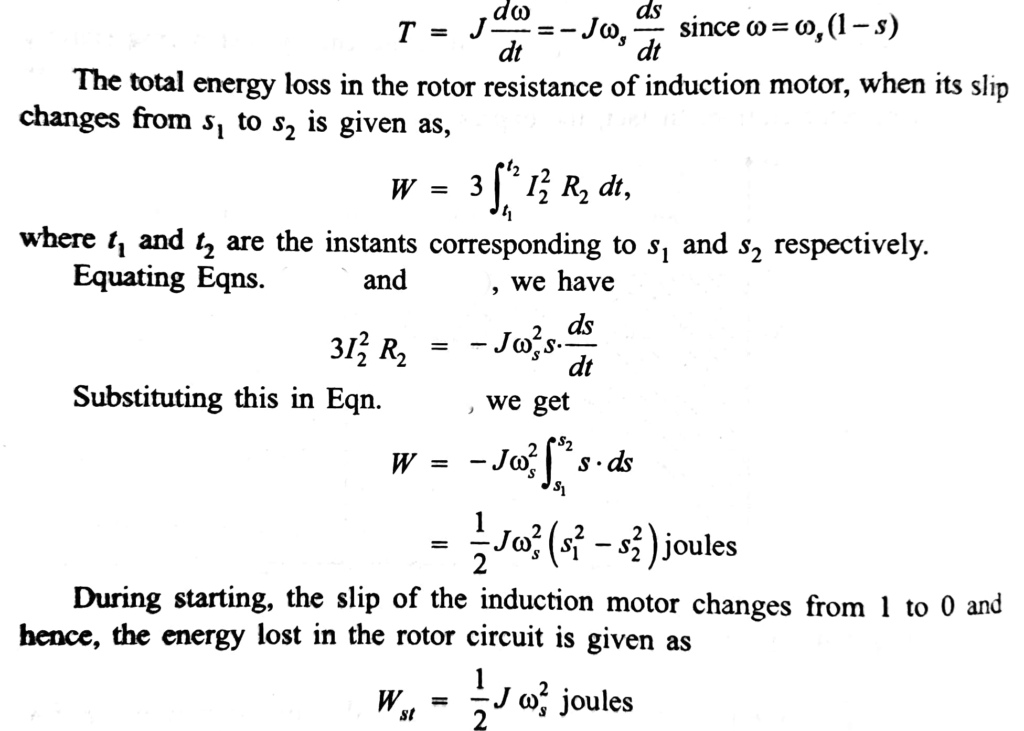

3. Three Phase Induction Motor

Now, let us consider a three-phase induction motor. The expression gives the torque developed

T = 3 / ωs. I22 . R2 / s

Neglecting load and friction torques in the motor, we have

Methods to Reduce the Energy Loss During Starting

The following methods are commonly used to reduce the loss of energy during starting of motors:

(i) Reducing the moment of inertia of the rotor,

(ii) Starting of DC shunt motors by smooth adjustment of applied voltage,

(iii) Starting of multispeed induction motors in discrete steps of speed, and

(iv) The induction motors are started by smooth variation of supply frequency (Vif control).

Frequently Asked Questions (FAQs)

-

What is the effect of load on power supply?

In an unregulated DC power supply, as the load increases, the output voltage drops. It uses a rectifier and capacitor for smoothing but doesn’t regulate the voltage to keep it steady.

-

What happens when motor load increases?

When the load on a motor increases, it slows down and the torque and current rise. If the load exceeds the limit, the motor can eventually overheat.

Leave a Reply