Table of Contents

Introduction

A solar dryer is a device that uses the power of the sun to dry fruits, vegetables and crops for preservation. There are two types: direct and indirect.

In direct solar dryers, the substance to be dried is placed under the open sun in a large area. In indirect solar dryers, there is an insulated box with a black surface inside, an air inlet, an air outlet, and a glass cover. The black surface absorbs sunlight and heats up the inside of the box, which helps in drying the substance.

The principle behind the operation is based on the difference in air density. Cold air enters through the lower inlet, and the warm air inside the box, created by the sun’s heat, dries the substance. The moisture-rich hot air then exits through the upper outlet due to the difference in air density.

In simple terms, the sun’s heat dries the fruits or crops inside the box, and the warm, moist air is pushed out through the top while fresh, cool air comes in from the bottom. This process helps in preserving the food without using any electricity or fuel.

Working Of Solar Drying

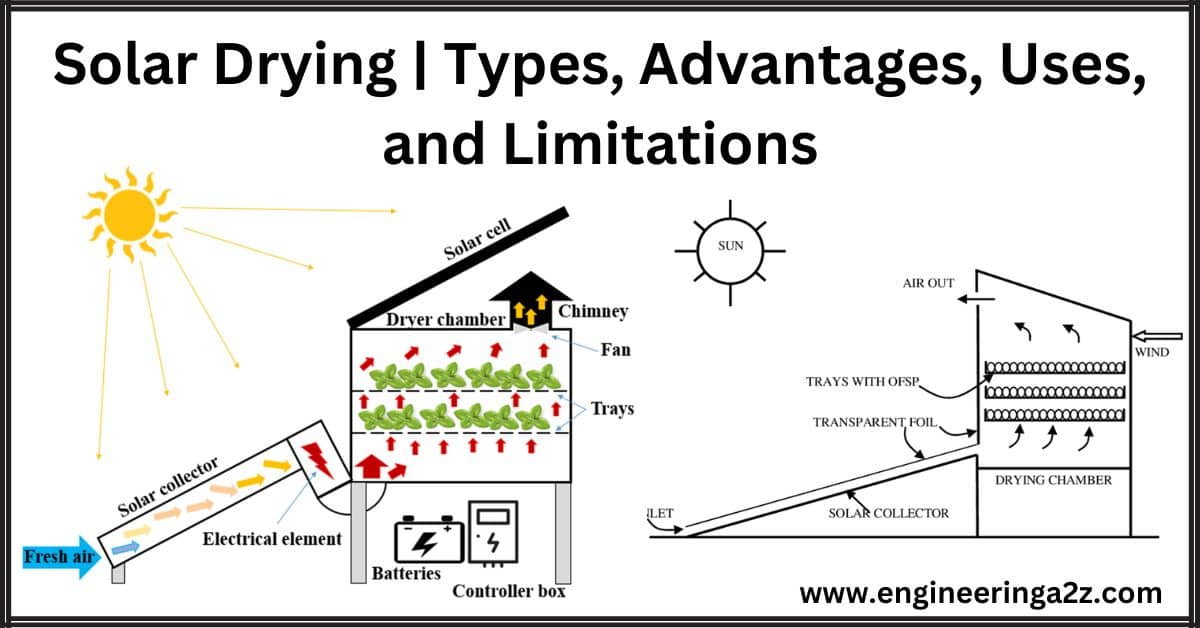

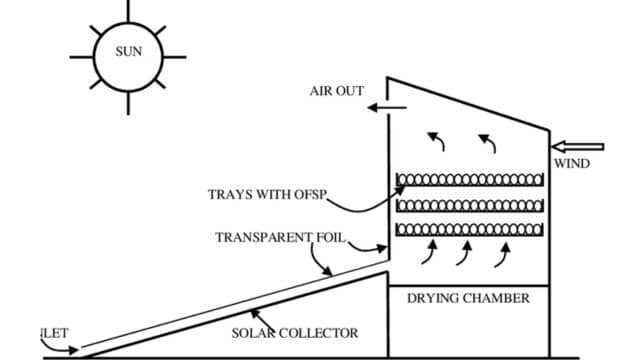

The principle of the solar drying technique is to collect solar energy by heating the air volume in solar collectors and to lead the warm air from the collector to the drying chamber. The products to be dried are placed in the drying chamber.

The basic principles employed in a solar dryer are:

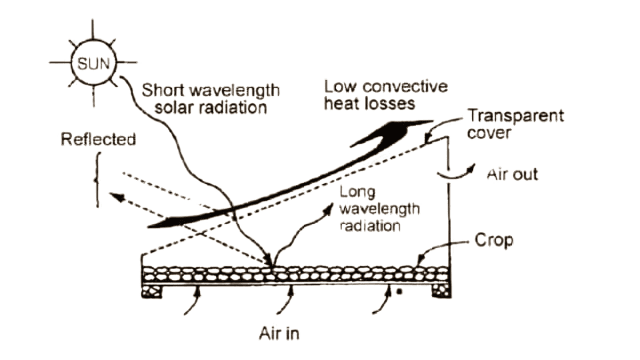

- Converting light to heat: Using black surfaces on the inside of a solar dryer is beneficial because black surfaces absorb more sunlight and convert it into heat more efficiently than other colors. When light hits a black character, it is absorbed rather than reflected, and this absorbed energy is then converted into heat. By having black surfaces inside the solar dryer, the absorbed light energy can raise the temperature, promoting more effective drying of the materials placed inside.

- Trapping heat: Using explicit solid materials like plastic bags or glass covers as a covering for the solar dryer is an effective way to trap the heat inside. These materials allow sunlight to pass through and reach the drying chamber, which is converted to heat, but they have a high infrared radiation reflectivity. As a result, once the light energy is converted to heat, it is less likely to escape through the transparent cover, thereby trapping the heat inside the dryer. This is particularly useful on cold and windy days when external heat loss would be significant.

- Moving the heat to the food: The heat generated inside the solar dryer must be efficiently transferred to the dried material. Both natural convection dryers and forced convection dryers use the principle of convection to achieve this. In natural convection dryers, the warm air inside the chamber rises due to its reduced density and carries the heat towards the material being dried. Cooler and moist air from the surroundings replaces the rising warm air, creating a continuous convection cycle.

In forced convection dryers, fans or blowers are used to actively circulate the heated air inside the drying chamber. This forced circulation enhances heat transfer to the materials, ensuring more even and faster drying. The use of forced convection can significantly reduce the drying time compared to natural convection dryers.

By employing these principles of converting light to heat, trapping the heat, and efficiently moving the heat to the material being dried, solar dryers can achieve effective and efficient drying of various products while utilizing renewable energy from the sun.

Types OF Solar Drying

Solar Drying is classified into two types:

- Direct Solar Drying

- Indirect Solar Drying

1. Direct Solar Drying

Direct solar dryers expose the food or other items directly to the sunlight for drying. In the past, people used simple methods like hanging clothes on lines or laying food on rocks or tents to dry in the sun. Even now, some traditional practices in certain places, like Mongolia, involve using the top of a tent to dry cheese and meat in the sun.

In modern times, we have more sophisticated solar dryers. One type has a black surface that absorbs sunlight and turns it into heat. The substance to be dried is placed directly on this heated surface. These solar dryers might have covers, glass, or vents to make them work even better and more efficiently. The solar energy heats up the surface, which, in turn, helps to dry the food or other items placed on it.

2. Indirect Solar Drying

Indirect solar dryers work differently from direct ones. Instead of directly heating the substance, they heat the incoming air. This heated air is then passed over the substance to be dried, taking away the moisture released from it. The heated air exits through a chimney, carrying the moisture with it.

These dryers can range from simple setups like a tilted frame with black cloth to more complex structures like insulated brick buildings with active ventilation and backup heating systems.

Indirect solar dryers have some advantages. They protect the food or substance from contamination by wind-blown debris or pests like birds, insects, and animals. Additionally, they prevent direct sunlight from chemically altering some foods, which can make them less appetizing.

The temperature inside solar dryers is usually kept between 50-70 degrees Celsius. Modern solar dryers, such as Vyom and others, use materials like polycarbonate sheets or UV preventive glass to protect the food from harmful UV rays that can degrade the dried food. These solar dryers not only speed up the drying process but also keep the food safe from dust, pathogens, bird droppings, and other external elements that could affect its quality.

Drying food using solar dryers allows fruits, vegetables, spices, and other items to be preserved for a longer time. It helps in extending the shelf life of these foods, making them available even when they are out of season or in limited supply.

Advantages of Solar Drying

- Less product contamination with a transparent cover.

- Protection from rain, dew, and debris.

- Higher product quality than open sun drying.

- Simple and cost-effective construction.

Disadvantages of Solar Drying

- Crop damage from rodents, birds, and animals.

- Deterioration from direct sun exposure, rain, storms, and dew.

- Contamination from dirt, dust, debris, and pollution.

- Losses from over-drying.

- Infestation by insects and growth of microorganisms.

- Additional losses during storage due to inadequate or uneven drying.

Applications of Solar Drying

- Solar dryers are cheaper than conventional fuel/electricity dryers.

- They dry things in a clean and eco-friendly manner.

- Operating and maintaining them costs less, and they last longer – around 15-20 years with little upkeep.

Limitations of Solar Drying

- Solar drying can only happen on sunny days unless it’s combined with a regular energy-based system.

- Solar dryers are slower than those using conventional fuels due to limited solar energy collection.

- They are typically used for drying at temperatures between 40-50 degrees Celsius.

Frequently Asked Questions (FAQs)

What is Solar Drying?

The natural drying method uses solar energy to preserve food and other materials. Efficient, eco-friendly, and cost-effective.

What is the purpose of Solar Drying?

Solar dryers are used to remove moisture from crops, vegetables, and fruits. They’re made from affordable materials like cement, iron, brick, and plywood. The top is covered with clean sheets.

What are the examples of Solar Drying?

1. Solar drying of tea leaves to produce flavorful and aromatic tea.

2. Drying nuts such as almonds and walnuts to extend their shelf life.

3. Preparing dried mushrooms using solar dryers.

4. Solar drying of seaweed for use in various food products or supplements.What is the capacity of Solar Dryer?

It is designed to keep dust, rodents, bugs, insects, and water out. It can dry 2 to 5 kg of material per day, depending on its weight and volume. Available in capacities of 10 kg, 25 kg, 50 kg, 100 kg, and 200 kg per day.

Related Posts

- Solar Cell or Photovoltaic Cell Construction and Working

- Nuclear Power Plant | Working | Advantages & Disadvantages

- B.Tech – Electrical Engineering Previous Year Question Papers Download

- Hydroelectric Power Plant | Working | Advantages and Disadvantages

- Thermal Power Plant | Working | Advantages and Disadvantages

- Gas Turbine Power Plant | Working | Selection of Site

Leave a Reply