Table of Contents

Rating and Heating of Motors

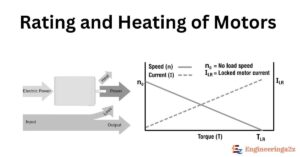

The size and rating of an electric motor essential for driving various applications, are influenced by multiple factors that ensure efficient and safe operation. These include heating effects within the motor, loading conditions, load inertia and environmental factors. Motors generate heat due to internal losses and their ability to dissipate this heat determines their temperature rise and performance under continuous operation.

The size and rating of a motor to be used as a drive element in a particular application depend upon the following factors:

- (i) Heating effects in the motors

- (ii) Loading conditions and classes of duty

- (iii) Load inertia or inertias

- (iv) Environmental conditions.

1. Heating Effects

The heating of a machine is a function of the losses within it that are developed as heat. The cooling depends upon the facilities for heat dissipation, i.e., ventilation, to outside media such as air, oil, or solids. The temperature rise depends on the inter-relationship between heating and cooling. Under steady-state conditions, the final temperature rise is reached when the rates of production and dissipation of heat are equal.

Electrical machines are designed for a limited temperature rise. In fact, the continuous rating of a machine is that rating for which the final temperature rise is equal to or just below the permissible value in temperature rise for the insulating material used in protecting the conductors. When the machine is overloaded for such a long time that its final temperature rise is higher than the allowable limit, it is likely to be damaged.

In worst cases, this will result in an immediate thermal breakdown of the insulating material which will cause a short circuit in the motor, thus putting a stop to its functioning. The short circuit may also lead to a fire. In less severe cases immediate thermal breakdown of the insulating material may not occur, but the quality of the insulation will deteriorate such that thermal breakdown with future overloads or even normal loads might soon occur, thus shortening the useful life of the machine.

For the permissible temperature limits on commonly used insulating materials, ISS: 1271 should be consulted. Since class A insulated machines are not considered as standard machines, the insulation-system classes of main interest for machines used in industry are class E, class B, class F and class H. ISS: 4722 limits permissible temperature rise for the various parts of rotating electrical machines. Fairly detailed distinctions are made as regards the type of machine, machine part involved, method of temperature, measurement, the type of cooling (air cooled, hydrogen cooled etc.) and class of duty.

2. Loading Conditions and Classes of Duty

An electric motor, under steady state operation, develops electromagnetic torque of such a magnitude which can counterbalance the actual load torque TL of the connected equipment and an opposing torque Tmech , corresponding to the losses that take place in gear and transmission mechanisms. Under transient conditions, the motor torque has to overcome the inertia torque Tdyn also. Hence, in general, the torque developed by the motor should be expressed as:

T = TL + Tmech + Tdyn

The combined load torque ( TL +Tmech ) is determined from the torque-time plot of the connected load. A is shown in Fig.(a). In order to determine the variation of inertia torque with respect to time, the speed-time curve, an example of which is shown in Fig.(b) and the moment of inertia of the rotating masses / must be known. Now, with the help of Eqn. it will be possible to obtain the torque-time curve of the driving motor [(c)]. which is called the duty cycle of the motor.

Since, initially remains unknown, the torque-time graph can be plotted by taking into account only TL and Tmech. After determining the power rating of the machine using the above torque-time graph, it can be corrected for the presence of inertia torque by increasing the rating obtained by 15-20 per cent. Knowing Jof the chosen motor, the exact torque-time curve can be plotted and a more correct estimation of the rating of the driving motor can be made.

The rating of a motor selected from the viewpoint of heating depends on the load conditions or duty to which it is subjected. According to ISS: 4722, these operating conditions are classified into eight classes of auty, depending on the duration and nature of the load, viz., continuous duty, short time duty, intermittent periodic duty, intermittent periodic duty with starting, intermittent periodic duty with starting and braking, continuous duty with intermittent periodic loading, continuous duty with starting and braking and continuous duty with periodic speed changes.

3. Determination of Power Rating of Electric Motors for Different Applications

(1) Continuous Duty and Constant Load

For most of the applications, the rating can be determined from the expression

P = (TN) / (975η). kW

where T is the load torque in kg-m, N the speed in rpm and n the product of the efficiency of the driven equipment and that of the transmitting device. In case of linear motion, the rating of the motor required is given by

P = Fv / (102η) . kW

where F is the force caused by the load in kg and v the velocity of motion of the load in m/sec.

The above expression is directly applicable in case of hoisting mechanisms. It is also suitable for lifts or elevators; but since a counterweight which balances the weight of the cage or car as well as one-half of the useful load will be always present, it should be modified as follows:

P = Fv /(2.102η) . kW

The velocity of the normal passenger lift cabins vary from 0.5 to 1.5 m/sec. In case of pumps, the rating can be determined from

P = (ρHQ) / (102η). kW

where

- p – density of the liquid pumped, kg / m3

- H – gross head (static head+ friction head), m

- Q-delivery of the pump, m3 /sec.

η varies from 0.8 to 0.9 for reciprocating pumps and from 0.4 to 0.8 for centrifugal pumps.

Similarly, the rating of a fan motor is given by

P = (Qh)/(102η) . kW

where Q is the volume of air or any other gas in m3 /sec and h is the pressure in mm of water or in kg / m2 For small power fans, the efficiency η may be taken as 0.6 and for large power ones it may reach a value upto 0.8.

The rating of a motor used in metal shearing lathes can be found from

P = (Fv)/(102 . 60 . η) . kW

where

- Q – shearing force, kg;

- v – velocity of shearing, m/min;

- n – mechanical efficiency of the lathe.

(2) Continuous Duty and Variable Load

The rating of a motor for such operating conditions can be determined on the basis of average losses. In this method it is assumed that the temperature rise attained by the motor with variable loading conditions over a certain period of time will be the same as that reached by the motor with a certain constant magnitude of load. The above will be true provided that the average losses in the motor for the same time are the same for both the conditions of operation.

Let us first assume a load-time graph as shown in Fig. It has different load torques corresponding to different intervals of time, including a period of rest (motor de-energized from the supply).

Average losses over the total period of time

= WL1. t1 + WL2. t2 +…….+ WLn . tn / t1 + t2 +……+ tn + to

where WL1, WL2, ….., WL3 are the losses that occur in the motor during the intervals t1, t2 ,…,tn etc. Note that no losses occur during the time interval to.

For an assumed constant current Ieq which causes the same average losses over the period of time considered, average losses can be written as (Wc + I2eqR) where WC and R denote the constant losses (core + mechanical losses the resistance of armature circuit of the motor.

4. Effect of Load Inertia

The principal load on motors driving loads of heavy inertia and having frequent starts is the acceleration and braking of the rotating masses. The load torque acting on the motor shaft is practically negligible. Rating of drives of such equipment essentially depends on the variation of torque during acceleration and braking. The power rating of the motor will be proportional to the product of rated torque and maximum speed of the motor.

In actual practice, such loads have permissible limits of speed of rotation, torque and acceleration. For example, constructional, requirements of the excavator specify the angular speed of turning ω0, angular acceleration A and the moment of inertia of the turning part of the excavator. Hence, it is convenient to determine the rating of the drive starting from the above-mentioned parameters.

5. Load Equalisation

Certain loads fluctuate very widely within short intervals of time. Electric hammers, presses, reciprocating pumps and steel billet rolling mills belong to such category of loads. When the motor is subjected to heavy loads, it will draw large current from the supply. These sudden peak demands of current, in addition to causing heavy losses, give rise to appreciable voltage drop in the lines and mechanical forces between the conductors carrying the current.

If the fluctuating load were to be a predominant one among those connected to the supply busbars, the other loads connected to the same supply lines would be subjected to undesirable voltage fluctuations. Therefore, it is necessary to smoothen out the load fluctuations. This process is called load equalisation.

Load equalisation is often achieved by means of a flywheel, which is mounted on the motor shaft, if the speed of the motor is not to be reversed. In case of reversing rolling mills, the flywheel is mounted on the motor-generator set feeding the driving motor. The driving motor should have a drooping speed characteristic so that the flywheel operates effectively. During intervals of heavy load, speed of the motor decreases.

This enables the flywheel to release a portion of the stored kinetic energy, which together with the energy drawn from supply, will meet the demand of load. During off peak load period, the motor draws more energy than required by the load. The surplus energy taken is again stored as kinetic energy in the flywheel, whose speed, then, increases.

6. Environmental Factors

A 100 kW motor of intermittent rating might be rated for 200 kW, if continuously operated at the North Pole at an ambient temperature of -80°C, since all the heat generated would still not be sufficient to overheat the motor under such ambient conditions.

At high altitudes the reduced air density decreases the cooling effect. The limitation is negligible for elevation less than 1000 m above sea level. For heights greater than 1000 m, the rating of the machine should be reduced according to the figures in the table below:

| Height above sea level, m Output for motor speed up to | 0 – 1000 | 2000 | 3000 | 4000 |

| 1000 rpm, per cent Output for motor speeds above | 100 | 95 | 90 | 85 |

| 1000 rpm, percent | 100 | 92 | 85 | 77 |

Totally enclosed machines without auxiliary forced ventilation, which do not permit ventilation and replacement of internal air, do not have as high a rating as similar machines, which are not totally enclosed and which are ventilated in such a manner that fresh air is drawn across the stator and rotor windings.

Frequently Asked Questions (FAQs)

What is the rating of a motor?

A motor is a device that takes electricity and turns it into movement or work. The power of a motor is usually measured in Horsepower (HP). Horsepower is just a way to measure how strong or powerful something is.

1 horsepower is about the same as 746 watts or 0.746 kilowatts. So, if a motor has 1 HP, it’s like using 746 watts of electricity to create motion or do work.What is a full-rated motor?

There are two types of motors: full-rated and up-rated.

1. Full-rated motors are built to handle more work and have a higher service factor, which means they can safely handle extra load if needed.

2. Up-rated motors have a lower service factor, so they can’t take as much extra load.

Leave a Reply