Table of Contents

Ocean Thermal Energy Conversion

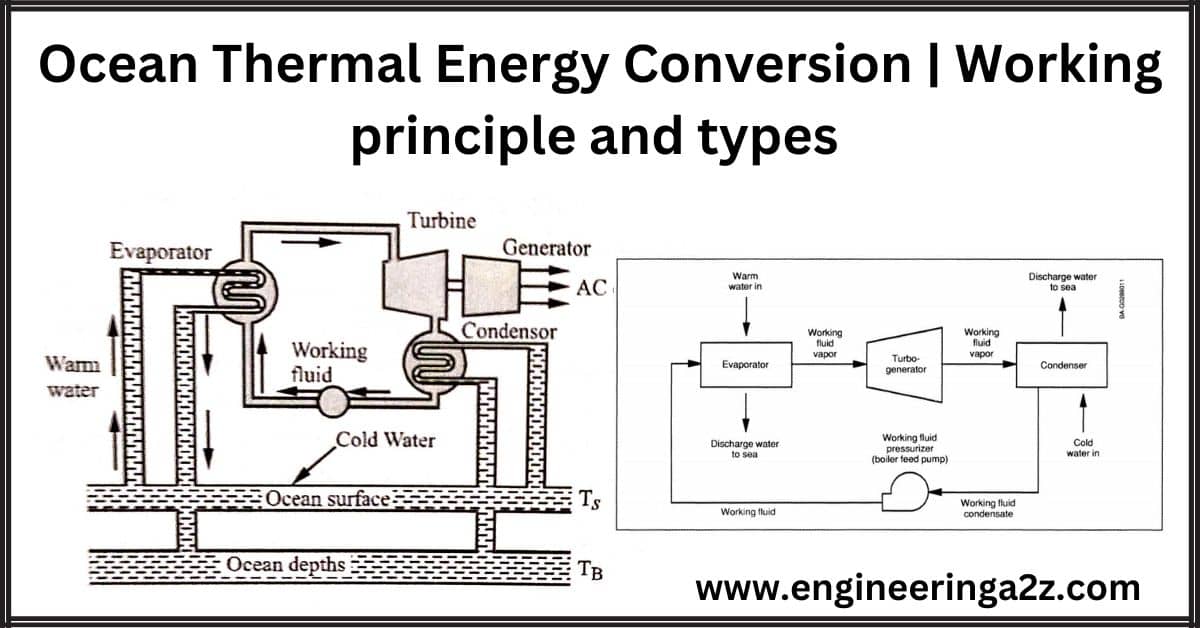

Ocean Thermal Energy Conversion (OTEC) is a renewable energy technology that utilizes the temperature difference between warm surface waters and cold deep waters in tropical oceans. The process involves circulating a working fluid, such as ammonia, between a surface heat exchanger and a deep-water heat exchanger. The warm surface water heats the working fluid, causing it to vaporize and drive a turbine connected to a generator, producing electricity.

The cold deep water is used to condense the vapour back into a liquid. OTEC has the potential to provide continuous, clean energy without greenhouse gas emissions, while also enabling other benefits like desalination and aquaculture. However, it faces challenges related to high upfront costs, technical complexity and environmental impacts on marine ecosystems.

Working Principle of OTEC Plant

OTEC (Ocean Thermal Energy Conversion) is a method of generating electricity by utilizing the temperature difference between warm surface water and cold deep water in the ocean. Here is a simplified explanation of how an OTEC plant works :

- Collection of warm surface water: The OTEC plant is typically located in a tropical or subtropical region where there is a significant temperature difference between the surface and deep ocean waters. Large-diameter pipes called “cold water pipes” or “seawater intake pipes” are deployed to depths of around 1,000 meters (3,280 feet) or more. These pipes collect warm surface water, usually with temperatures around 20 to 25 degrees Celsius (68 to 77 degrees Fahrenheit).

- Evaporation process: The warm surface water is pumped through a heat exchanger called the “evaporator.” In the evaporator, a low-pressure liquid (often ammonia) with a low boiling point is circulated in a separate closed-loop system. As the warm surface water passes through the evaporator, it heats the working fluid, causing it to evaporate into steam.

- Power generation: The high-pressure steam produced from the evaporator is directed toward a turbine. The steam expands in the turbine, spinning its blades and driving a generator, which converts the mechanical energy into electrical energy. This process is similar to conventional power plants that use steam turbines.

- Cold water condensation: After passing through the turbine, the now low-pressure and cooler steam enters a condenser. Cold deep ocean water, usually with temperatures around 5 to 10 degrees Celsius (41 to 50 degrees Fahrenheit), is pumped through another set of pipes called “warm water pipes” or “sea water discharge pipes.” The cold water circulates inside the condenser, causing the steam to condense back into a liquid state.

- Heat rejection: The heat extracted from the steam is transferred to the cold water from the deep ocean, which absorbs the excess heat. The cold water is then discharged back into the ocean, completing the cycle.

- Additional applications: OTEC plants can also utilize the temperature difference to produce freshwater through a process called “desalination.” As warm surface water passes through the evaporator, it can be used to evaporate seawater, leaving the salt behind. The resulting steam can then be condensed to produce fresh water.

It’s important to note that OTEC technology is still in the early stages of development, and large-scale commercial OTEC plants are limited in number. There are several variations of OTEC systems, such as closed-cycle and open-cycle systems, each with its own design considerations. The efficiency and viability of OTEC plants depend on factors such as the temperature differential, availability of suitable sites and economic considerations.

OTEC system

The system converts the thermal energy of hot surface water of the sea into electrical and other forms of energy because of the temperature gradient existing between the surface and deep seawater. There are potentially three basic types of OTEC power plant cycles to be utilized as below :

- (a) Open cycle

- (b) Closed cycle

- (c) Hybrid cycle.

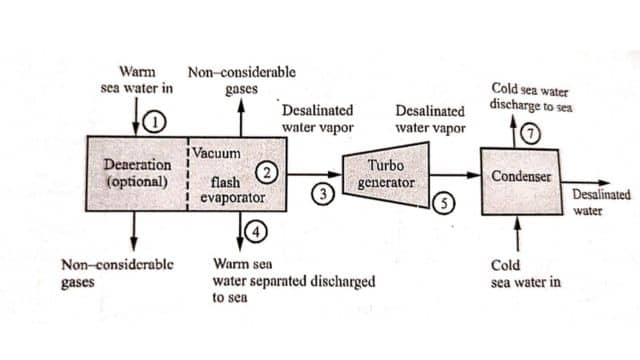

1. Open Cycle or (Clude Cycle)

An open-cycle OTEC system operates similarly to a closed-cycle system, but with a few notable differences. In an open-cycle OTEC plant, there is no intermediate working fluid involved. Instead, the warm surface water directly enters a vacuum-flashed evaporator, where it is transformed into low-pressure vapour in a vacuumed environment. This process requires a significant vacuum pump to create the necessary conditions.

Here is a breakdown of the steps involved in the open-cycle OTEC process :

- Warm surface water intake: The warm seawater from the ocean surface is pumped into the flash evaporator, denoted as step (1-2) in the process.

- Flash evaporation: In the flash evaporator, the warm sea water is subjected to low pressure and vacuum conditions, causing it to rapidly vaporize and form steam. This step is represented as (1-2) in the process.

- Steam production: The depressurization process continues from (2) to (3), resulting in the complete vaporization of the seawater and the production of steam. This steam is then directed to the low-pressure turbine, represented as (3-5) in the process.

- Power generation: The steam generated in the previous step is used to drive a large-diameter low-pressure turbine (around 12 m/MW of the steam plant). The turbine is connected to a generator, which converts the mechanical energy of the turbine into electrical energy.

- Warm water discharge: The warm water separated from the evaporator, depicted as (4) in the process, is discharged back into the ocean at the bottom. This step completes the cycle for the warm water.

- Steam condensation: After leaving the turbine, the steam enters a contact-type condenser, represented as (5-7) in the process. Cold water from the depths of the ocean is pumped into the condenser to facilitate the condensation of the steam back into liquid form.

- Desalination and utilization: The condensed water obtained from the condenser is desalinated water, which can be utilized for various purposes. This water is typically free of salt and can be used for drinking, agriculture, or other applications.

- Cold water intake: The cold deep water from the ocean, after being used in the condenser, is discharged back into the sea, where it meets the low-temperature seawater. This step is denoted as (6) in the process.

The open-cycle OTEC system requires a large turbine due to the significant volume of low-pressure steam involved (typically around 0.02 bar). Additionally, the plant necessitates a substantial amount of pumping work due to the large quantities of warm and cold water handled, which is a result of the low-temperature difference between the water sources.

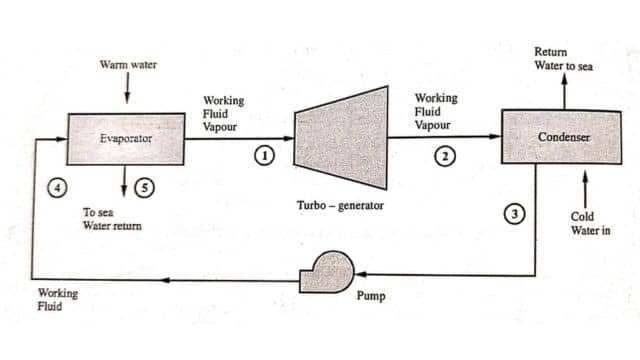

2. Closed Cycle or (Anderson Cycle)

In a closed-cycle OTEC system, the warm surface water does not directly vaporize. Instead, it heats an intermediate working fluid with a low boiling point, such as ammonia or freon, in the evaporator (heat exchanger).

- Warm surface water intake: The warm seawater is directed into the evaporator, where it transfers heat to the intermediate working fluid (ammonia or freon).

- Heat transfer and vaporization: The warm surface water in the evaporator raises the temperature of the intermediate working fluid, causing it to vaporize into a high-pressure gas.

- Power generation: The high-pressure gas from the evaporator is directed to drive the turbines, which are connected to generators to produce electricity.

- Condensation: After passing through the turbine, the high-pressure gas (now at a lower pressure) enters the condenser. Cold water from the deep sea is used to cool the gas, causing it to condense back into a liquid state.

- Heat rejection and circulation: The condensed liquid working fluid is pumped back to the evaporator to restart the cycle. At all times, the working fluid remains in a closed system and is continuously circulated by a pump.

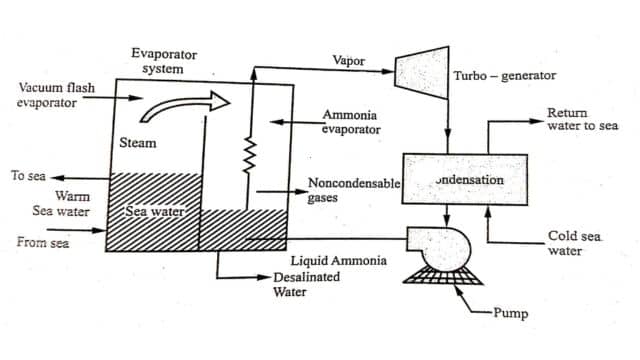

3. Hybrid Cycle

This cycle is a combination of open and closed cycles. The overall thermal efficiency of a hybrid system is higher than the other two systems. The hybrid systems are used to produce electricity as well as desalinated water.

There are two concepts of the hybrid system. The first one is to use a closed-cycle OTEC to generate electricity and produce desalinated water. The necessary low-pressure environment for the open cycle OTEC is produced in the flash evaporator to flash the water vapor. The water gets evaporated in a vacuum chamber and is condensed back in the second ammonia evaporator to produce desalinated water as in an open cycle. The intermediate secondary fluid (ammonia) gets evaporated in this chamber and enters the turbine as in a closed cycle to produce turbine work to generate electricity. The noncondensable gases are removed from the ammonia evaporator and are discharged into the atmosphere.

The second concept is to integrate two open cycles OTEC, one cycle is used to run the turbine. This work is utilized to create the vacuum environment in the heat exchanger. In this cycle, there will be twice the amount of desalinated water produced.

Advantages of OTEC Plant

- Renewable energy: OTEC harnesses the ocean’s thermal energy, providing a renewable and sustainable source of power.

- Baseload power: OTEC can generate electricity consistently, offering a reliable baseload power supply without relying on intermittent sources like solar or wind.

- Environmentally friendly: OTEC plants have low greenhouse gas emissions and do not contribute to air pollution, making them environmentally friendly compared to fossil fuel-based power generation.

- Integrated desalination: OTEC can produce freshwater through desalination, addressing water scarcity issues in coastal regions.

- Potential for additional applications: OTEC has the potential for diverse applications such as aquaculture, supporting economic growth, and food security in coastal areas.

Disadvantages of OTEC Plant

- Limited scalability: OTEC plants currently face challenges in scaling up to large capacities. The technology is still in the early stages of development, and implementing larger-scale OTEC plants may require further advancements and infrastructure modifications.

- Energy transmission: OTEC plants located far from coastal areas may face challenges in transmitting the generated electricity to the mainland grid. Overcoming transmission losses and establishing efficient power transmission infrastructure can be a significant hurdles.

- Competition with other renewable energy sources: OTEC faces competition from other well-established and economically viable renewable energy sources such as solar and wind power. These alternatives may offer more cost-effective solutions, potentially limiting the widespread adoption of OTEC technology.

Applications of OTEC Plant

- Power generation: The primary application of OTEC plants is to generate electricity. OTEC can provide a reliable and continuous source of power, particularly in tropical and subtropical regions with suitable oceanic conditions.

- Desalination: OTEC plants can integrate desalination processes to produce fresh water. The temperature gradient in OTEC systems can be utilized to evaporate seawater and obtain fresh water through condensation, addressing water scarcity issues in coastal areas.

- Aquaculture: The nutrient-rich cold water discharged from OTEC plants can be utilized for aquaculture, promoting the farming of marine species. This supports the growth of fish and other aquatic organisms, enhancing food security and economic opportunities in coastal regions.

- Cooling and air conditioning: OTEC plants can be utilized for cooling applications, especially in coastal areas with high cooling demands. The cold water from deep ocean depths can be used for air conditioning and refrigeration, reducing the energy consumption associated with traditional cooling systems.

Frequently Asked Questions (FAQs)

-

What is Ocean Thermal Energy Conversion (OTEC)?

Ocean Thermal Energy Conversion (OTEC) is a method to generate electricity using the temperature difference between warm surface water and cold deep water.

-

What are the limitations of the OTEC system?

1. The capital cost is more.

2. Difficult maintenance.

3. Construction of a floating plant is difficult. -

What are the applications of the OTEC system?

1. The enclosing area can be used for aquaculture and mariculture.

2. The deep sea cold water is rich in nutrients and can be used for various applications. -

What are the types of OTEC Systems?

There are three basic types pf OTEC power plant cycle.

1. Open cycle

2. Closed cycle

3. Hybrid cycle.

Related Posts

- Wind Energy | Engineeringa2z

- Waste to Energy | Methods, Economic Impact and Future Trends

- Types of Biomass Gasifier

- Tidal Energy | Working, Parts, and Applications

- Thermochemical Energy Storage | Principle, Types, and Requirements

- Thermal Power Plant | Working | Advantages and Disadvantages

Leave a Reply