Table of Contents

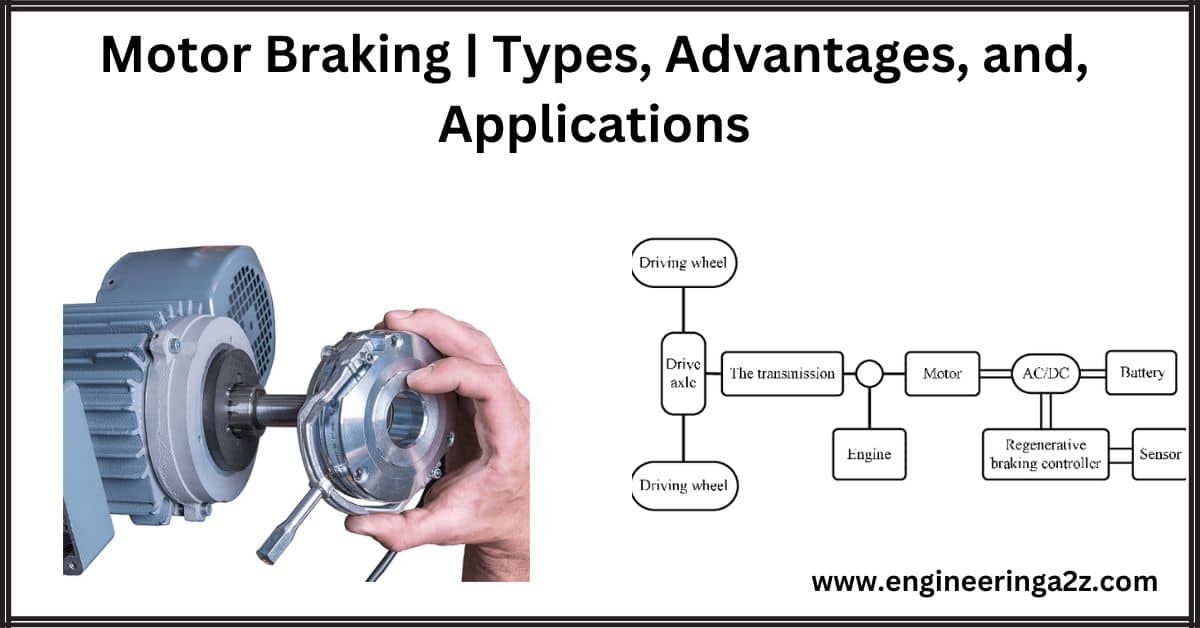

Introduction

Electric braking provides a more consistent and controlled way to rapidly stop a running motor compared to mechanical braking, which relies on the condition and quality of brake shoes and surfaces. This means that the effectiveness of electric braking is not affected by the condition of physical brake components, ensuring a smoother and more reliable braking experience.

The term “braking” originates from the concept of a “brake,” which is a device used to slow down or stop the movement of various objects, such as vehicles and locomotives. The act of applying brakes is referred to as “braking.” In this discussion, we’ll categorize braking into two main types:

- Mechanical Braking

- Electrical Braking

For our purposes on this electrical engineering platform, we’ll focus exclusively on electrical braking. Unlike mechanical braking, which relies on purely mechanical methods to reduce a machine’s speed, electrical braking is a more intricate process that hinges on controlling the direction of magnetic flux and torque. We will explore different forms of electrical braking, but the fundamental concept underlying all these methods is the alteration of flux direction.

Mechanical Braking

Mechanical brakes utilize mechanical components to decelerate or halt the motion of shafts within machinery systems. They employ levers or connections to transmit force from one point to another, effectively reducing or stopping the movement of the connected shafts. Various types of mechanical brakes exist for different applications.

Band brakes, known for their simplicity, feature a metal band coated with heat and wear-resistant friction material. When engaged, these bands exert pressure to slow down or stop the motion.

Drum brakes, frequently found on the rear wheels of automobiles, operate by having brake shoes press against a rotating drum surface, providing the necessary braking force.

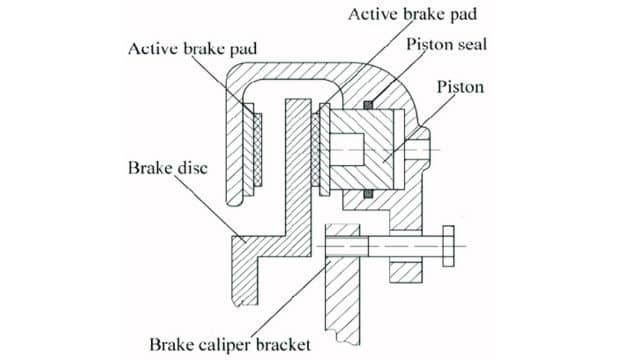

Disc brakes are constructed with brake pads, a caliper, and a rotor. In action, the brake pads are pressed against the rotor to achieve the desired braking effect.

Cone brakes consist of a cup and a cone, both lined with heat and wear-resistant material. During activation, the cone is pressed against the surface of the coupling cup to generate braking force.

1. Disc Brake

A disk brake is a device that helps slow down or stop a spinning wheel on a moving vehicle. It’s like a special kind of circle made of tough material, often iron or sometimes high-tech stuff like carbon or ceramic. This circle is attached to the wheel’s axle.

To make the wheel stop, we use something called a brake caliper with a friction material inside it. We push this material against both sides of the circle really hard, and that creates friction. This friction slows down and eventually stops the circle and the wheel. But when we do this, it also makes a lot of heat.

If we use the brakes too much and they get too hot, they won’t work as well. This is called “brake fade,” and it’s not a good thing because it means the brakes can’t stop the wheel effectively anymore.

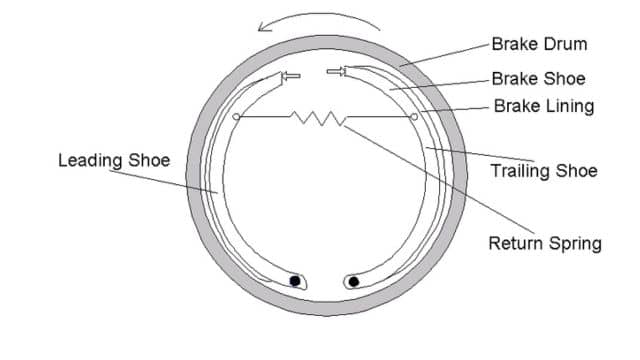

2. Drum Brakes

A drum brake is a type of brake that works by using pads or shoes to press against a round, drum-shaped part called a brake drum. When we talk about drum brakes, it usually means that these pads or shoes push against the inside of the drum. If the pads or shoes press against the outside of the drum, we call it a “band brake.”

Sometimes, there’s a setup where the drum gets squeezed between two shoes, sort of like a regular disc brake. In those cases, it’s occasionally referred to as a “caliper drum brake,” although you don’t see these types very often.

Another kind of brake uses a flexible strap or band that wraps around the outside of a drum, and we call that a “band brake.”

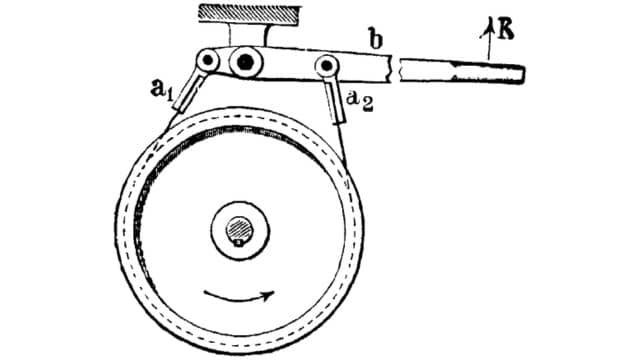

3. Band Brakes

Band brakes are a type of brake that you can find on things like bicycles, motorcycles, and machines. They work by using a flexible strap, like a belt, made from a strong material, and this strap wraps around a round drum. When you squeeze a lever or press a pedal, it makes this strap tighten around the drum.

The friction, or rubbing, between the strap and the drum slows down or stops the wheel from spinning. So, it’s like squeezing a belt around a spinning drum to make things stop. That’s how band brakes work.

Components of Mechanical Brakes

In simple terms, mechanical brakes have these important parts:

- Brake Shoes or Pads: These are like special blocks that press against a spinning part (either a drum or rotor) to make it slow down. They are made of a material that creates friction to do this job.

- Brake Drum or Rotor: This is the spinning part that the brake shoes or pads press against. When they rub against it, it makes the wheel slow down.

- Caliper or Brake Lever: This is like the hand that pushes the brake shoes or pads against the spinning part. It’s what makes the brakes work when you press the brake pedal.

- Brake Fluid: This is a special liquid used in some brakes to help the caliper or brake lever push the brake shoes or pads. It’s like the power that makes the brakes stop the wheel when you press the brake pedal.

Working Principle of Mechanical Brakes

Mechanical brakes function by transforming the energy of movement into heat energy through the process of friction. When you apply the brake pedal or lever, it causes the brake pad or shoe to press against the drum or rotor, generating friction. This friction changes the energy associated with the object’s motion into heat energy, which then disperses into the surrounding environment. Consequently, this action leads to the object either slowing down or coming to a complete stop.

Advantages of Mechanical brakes

- Reliability: Mechanical brakes are easy and dependable. They work well in tough places or when other brakes might not do the job.

- Cost-effective: Mechanical brakes are cheaper than other types. So, they’re a good choice if you want to save money and still get the job done.

- Easy to maintain: It’s simple to take care of mechanical brakes. If something breaks, you can replace just the part that’s broken. That means less time the brakes aren’t working and less money spent on fixing them.

Disadvantages of Mechanical brakes

- Low stopping power: Mechanical brakes don’t stop things as quickly as some other types like hydraulic or electromagnetic brakes. So, they’re not great for situations where you need to stop really fast, like high-performance situations.

- Heat buildup: Mechanical brakes get really hot when they work, and if they don’t cool down properly, it can damage them or make them work less effectively.

- Wear and tear: Mechanical brakes wear out over time, like how a shoe sole wears down from walking a lot. This means you have to change parts of the brake often to keep it working well.

Electric Braking

Electric braking is a method used to slow down or stop electric motors and machinery quickly and efficiently. It involves the use of electrical systems and components to create a braking force that opposes the motor’s motion, converting its kinetic energy into heat or other forms of energy dissipation. Electric braking is crucial in various applications, including machine tools, cranes, and elevators, where rapid stopping is essential for safety and precision.

Types of Electric Braking

Brakes are used to slow down or stop motors. There are different types of motors like DC, induction, synchronous, and single-phase motors, each with unique characteristics. Consequently, braking methods vary, but we can categorize them into three main types that work with most motors:

- Regenerative Braking

- Plugging type braking.

- Dynamic braking

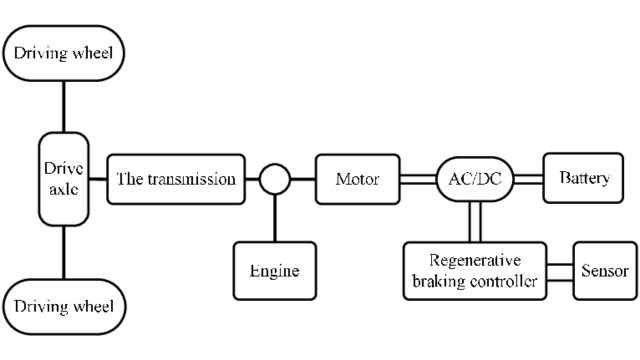

1. Regenerative Braking

Regenerative braking happens when a motor goes faster than its normal speed. In this method, the motor becomes a generator and uses the power it generates to slow itself down. To make regenerative braking work, the motor’s rotor (the part that spins) must go faster than its regular speed. When this happens, the direction of the electric current changes, and the motor starts slowing down.

The drawback of this braking method is that it can harm the motor because it needs to run faster than usual. However, if you have a variable frequency source, you can use regenerative braking even when the motor is slower than its normal speed, which is safer for the motor.

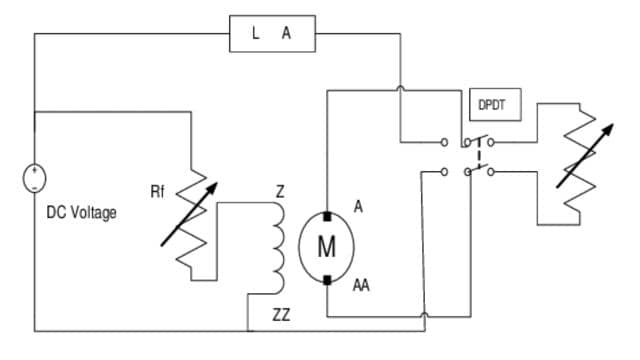

2. Plugging Type Braking

Plugging-type braking involves switching the power supply terminals to reverse the direction of the motor. This causes the motor to produce a torque that opposes its usual rotation, leading to a decrease in speed. During plugging, an external resistance is added to control the current flow. However, a significant downside of this method is that it results in energy being lost or wasted.

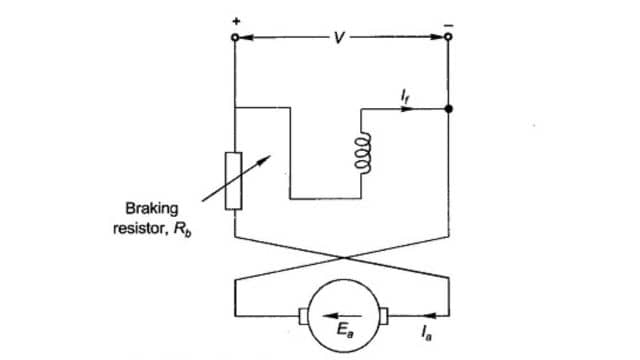

3. Dynamic braking

Dynamic braking, also known as rheostatic braking, is a less efficient way to slow down a motor because it converts kinetic energy into heat.

It works like this: First, the motor is disconnected from the power source. Then, a braking resistor is quickly connected to the motor. The motor’s kinetic energy is turned into electrical energy, which is mostly wasted as heat.

Regenerative braking, on the other hand, is more commonly used to control the speed of motors that drive things like elevators, trains, cranes, and hoists. It’s a more efficient way to slow down because it actually recovers some of the energy and puts it back into the system instead of wasting it as heat.

Advantages of Electric Braking

Here are the main points about mechanical and electric braking:

Mechanical Braking:

- Uses brake blocks and lining.

- Functions on friction, requiring frequent replacement and adjustments.

- Brake components wear out and need readjustment.

- Not suitable for heavy loads or high speeds.

- All braking energy is lost as heat.

- Can be rough and cause shocks if not adjusted correctly.

- Generates metal dust that can damage bearings.

- The heat produced can harm brake components and lead to failure.

Electric Braking:

- Maintenance-free.

- Ideal for higher speeds and heavy loads.

- Regenerative electric braking returns some energy, saving costs.

- Provides smooth and jerk-free braking.

- No generation of metal dust or bearing damage.

- The heat produced does not harm motor components.

- Faster compared to mechanical friction braking.

Disadvantages of Electric Braking

- Electric braking makes the motor act as a generator to slow down the machine.

- Electric braking can stop the motor but can’t hold it stationary, so a mechanical friction brake is needed for that purpose.

- Different motors have unique speed-torque characteristics, and motor selection should match the specific application.

- A motor suitable for one type of load may not work well for other loads.

- Specially designed motors for electrical braking can be costly due to their unique features and capabilities.

Applications of Electric Braking

- Gym Equipment: Many gym machines employ electric braking systems for precise control.

- Industrial Equipment: Numerous industrial machines and tools also rely on electric braking for efficient operation.

- Recreation Equipment: Various recreational devices, including those used for entertainment and leisure, incorporate electric braking mechanisms.

- Tesla Model S: Tesla’s Model S utilizes electric brakes since it operates solely on electricity or electrical energy.

Frequently Asked Questions (FAQs)

What are the types of Electric Braking?

1. Regenerative Braking

2. Plugging Braking

3. Dynamic BrakingWhat are the applications of Electric Braking?

1. Rides and Roller Coasters: Amusement park rides and roller coasters are equipped with electric brakes to ensure safety and control during the thrilling experience.

2. High-Speed Electric Trains: Modern high-speed electric trains employ electric brakes for effective deceleration and safety measures.What is Regenerative braking?

Regenerative braking converts a vehicle’s kinetic energy into electrical energy during deceleration, improving efficiency and reducing wear on traditional brakes.

Read Also:

- Electric Traction | Speed-Time Curve

- Advantages | Disadvantages and Applications of Electric Power

- Electrical Energy | It’s Unit and Examples

- Advantages of Electric Heating

Leave a Reply