Table of Contents

Heating Methods

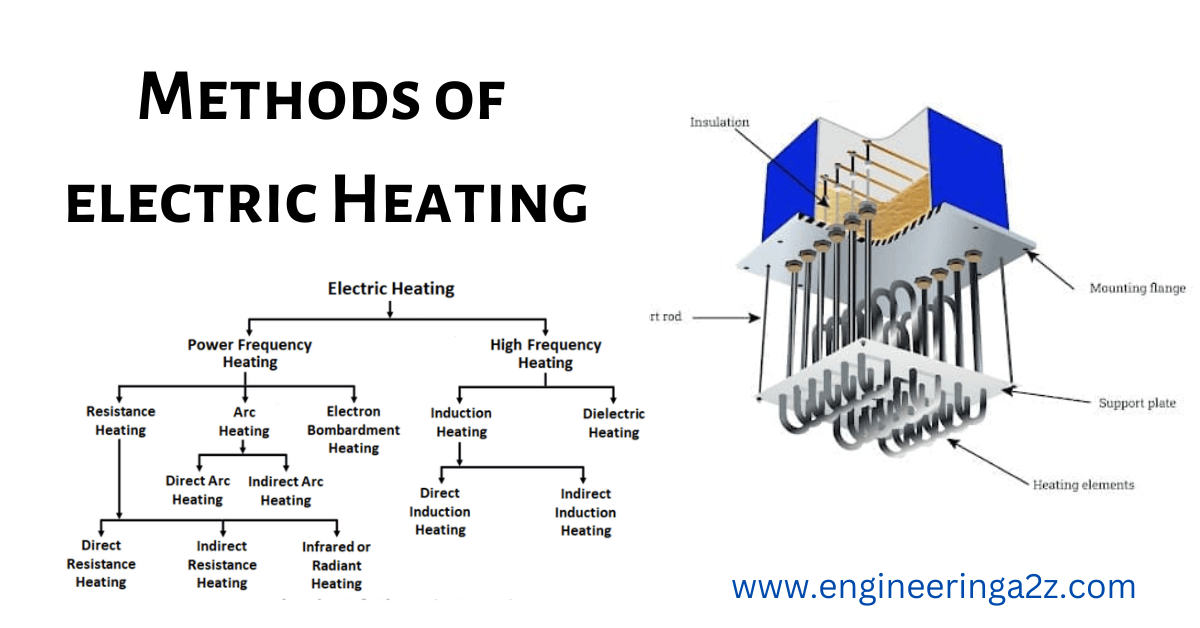

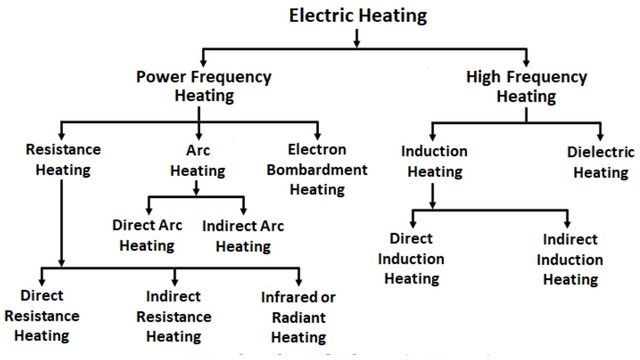

The conventional methods of producing heat by using firewood or coal has now been replaced by electrical heating methods. The electrical heating methods has several advantages over the conventional methods being used previously. In electrical heating methods heat is produced by passing current through a resistance. Heat used in domestic appliances like electric iron, room heater, geyser etc is produced by passing current through a high resistivity wire like nichrome. Now a days all heating requirements can be met with the help of electrical energy. There are several methods of electric heating:-

Read Also

What is Electric Heating

Resistance Heating

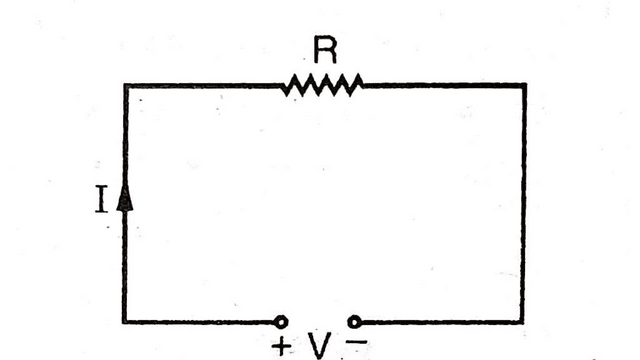

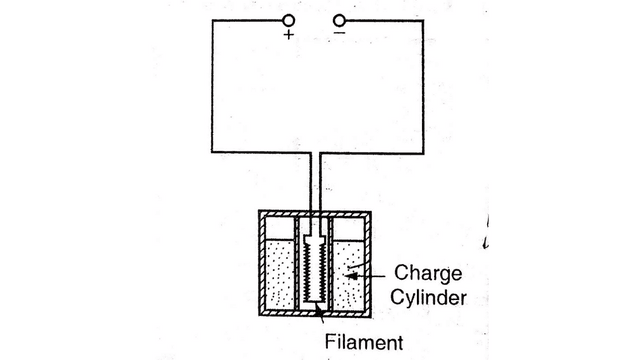

This is a power frequency method of heating i.e., power supply at 50 Hz is used for heating purposes. When a current I flows through a resistance , R for time t seconds heat produced is equal to I2R t Joules. Heat produced in a resistance on passing of current through it is due to power loss taking in it which appears in the form of heat.

The resistance wire is called Filament. If R is the resistance of the filament and V is the applied voltage then power loss is I2R t as shown in figure

Power loss occurring in a resistance = VI = V2 /R = I2 R watts

where V is the applied voltage. Resistance heating works efficiently on both AC and DC system. The overall efficiency of power frequency heating method is more than the high frequency heating method. Hence, resistance heating method is more efficient than induction or dielectric heating methods. Resistance heating method has good load factor and works on unity power factor.

This heating method is used for processes like hardening, annealing, (treatment of metals) baking, domestic cooking, drying of potteries etc. Temperatures upto 1000°C are obtained by using resistance heating method.

There are two different types of resistance heating methods

- Direct resistance heating

- Indirect resistance heating

This heat is transferred to the substances to be heated. The method of transfer of this heat gives two types of resistance heating.

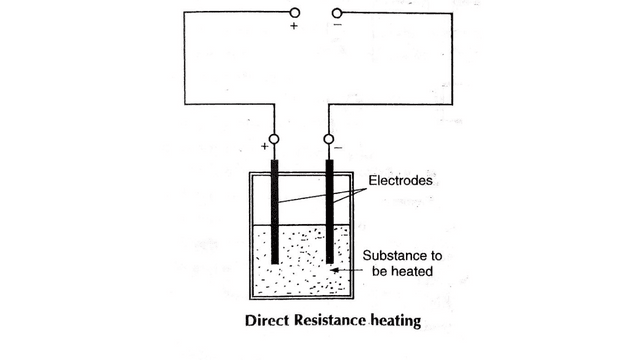

1. Direct Resistance Heating

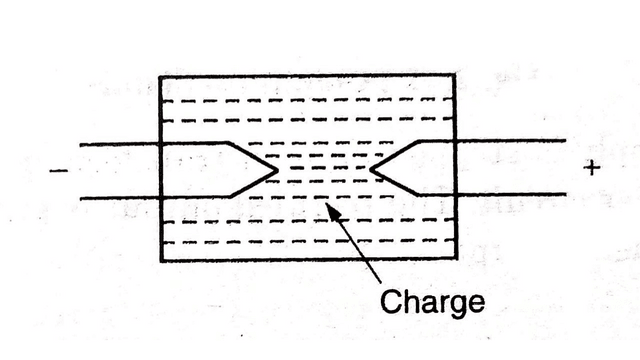

In this method current is passed through the substance directly. In other words the substance acts as filament itself. The current to the substance is given through the two electrodes. It can be seen that there are no power losses in this method. The material, also known as charge, can take the shape of tiny particles, liquid, or even powder. The supply delivered to electrodes submerged in the charge is either DC or AC. There are three electrodes in the case of a three-phase alternating AC supply.

If the charge is a metal, a powder substance is sprinkled over the charge’s surface to avoid a short circuit. When a voltage is given to the electrodes, current travels through the charge, resulting in power loss expressed as heat. This approach has a high efficiency since the heat produced is in direct contact with the charge. This technology produces very high temperatures and uniform heat. No Automatic temperature control can be provided in this method of heating.

Direct resistance heating method is generally used in salt bath furnaces and electrode boiler for heating water. The temperature of the salt bath depends upon the type of salt used. It usually range between 1000 to 1500°C. Carbonizing. hardening of steel tools, tempering etc uses salt bath furnaces. Direct resistance heating eliminates oxidation and provide uniform heating in salt bath furnaces. With increase in temperature of salt bath its resistance decreases. Tapping are provided to keep the current within limits as the resistance decreases. Current can also be controlled by changing depth of immersion and distance between electrodes.

Read Also

Induction Heating and its Types

Salient Features of Direct Resistance Heating

- Power at power frequency is supplied.

- Usually 30V, 3000 Amp is used to heat the substance.

- Automatic control is not possible.

- Uniform heating is obtained.

- This methods gives high temperatures for heating

- This method is utilized in water heaters and salt bath.

2. Indirect Resistance Heating

In this method of heating heat is not given directly to the charge, but, is transferred from the heating element to the charge by convection, radiation and sometimes by conduction method. This type of heating method is used in electric kettle, hot plate, soldering iron, toaster, water heater, hair drier, commercial cooking etc. An electric current is passed through an element of high resistivity which produces IR losses and appear in the form of heat.

When heat is transferred to the charge by method of either convection or radiation a heating chamber is used, where as in case of heat transfer by conduction method the heating element is in contact with the charge. Where large heating is required the heating element is kept in a enclosed cylinder around which charge is kept. This type of arrangement provides uniform heating. In indirect resistance heating automatic temperature control can be provided.

Salient Features of Indirect Resistance Heating

- This method gives uniform heating

- Automatic control is also possible.

- Any supply AC or DC can be used.

- Electric kettle, Electric Iron are example of this heating.

3. Infra-Red Heating

This is also called as Radiant heating. In this heating element is made of tungsten which operates at 2500°C and at this temperature, the element emits sufficient Infra red (IR) radiations. This temperature is higher than the resistance heating. The heating effect on the charge is greater. The heat emission efficiency may be upto 7200 Watt per m² which leads to heat absorption upto 4000 watt per m² This reduces time for various drying processes. This method is used for drying of paints, foundry moulds and heating plastics etc.

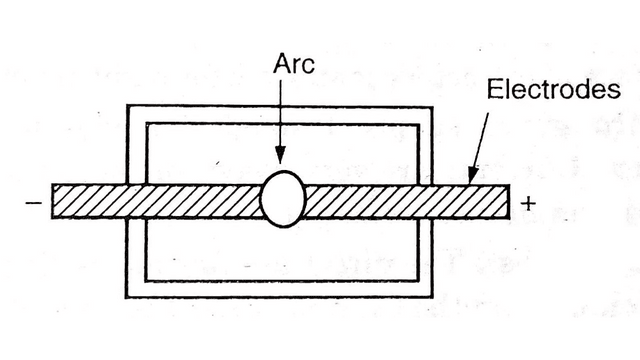

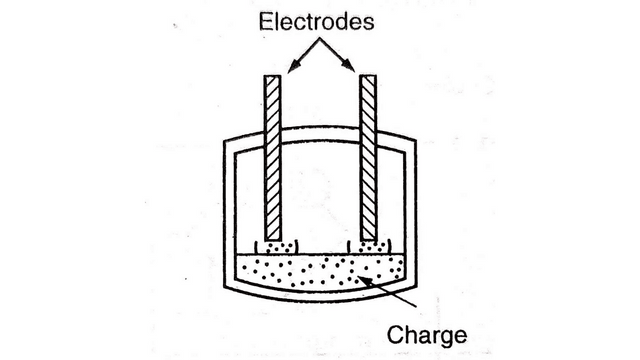

Arc Heating

When two electrodes are kept very close and connected with a high voltage supply, the current jumps from one electrode to the other and an arc is produced. This is the principle of arc heating. Generally two carbon or graphite electrodes are used with a small air gap. A high voltage is required to establish the arc but a lower voltage can maintain it. To start an arc, the electrodes are shorted together for a moment and then separated to a standard air gap so that the arc is maintained.

The temperature of the arc is about 3500°C which is sufficient to heat the charge.

The arc heating of following types:-

1. Direct arc heating

In this the arc is struct between the charge and the electrodes which are dropped from the top of the furnace.

2. Indirect arc heating

In this the arc is struck between electrodes which are fitted at the Centre of the furnace.

Frequently Asked Questions-FAQ’s

What are the types of power frequency heating?

1. Resistance Heating

2. Arc Heating

3. Electron bombardment HeatingWhat is electron bombardment heating?

Heating by electron bombardment (electron guns) :-An electrical technique in which high energy electrons released their energy as heat in the substance under treatment under varying degree of vacuum depending on the source of the electrons.

Write down Stephen Peterson formula for heating?

H=5.72 x 104 .Kε [(T1 /1000)4 – (T2 /1000)4 ] watt/m2 .

Related Posts

- Distributed Control System | Block Diagram and Architecture

- Radar | Types of Radar, Advantages and Disadvantages

- Unified Power Flow Controller | Control, Protection, and Charactersitcs

- Layout of Substations | Types, Advantages and Applications

- STATCOM | Static Synchronous Compensator

- SSSC | Operation, Modelling, and Applications

Leave a Reply