Table of Contents

Introduction

A fluidized Bed Gasifier is a process that turns waste material containing carbon into synthetic fuel gas and a small amount of inert char. Biosolids are fed into the gasifier with a controlled amount of oxygen. At high temperatures, a chemical process converts the biomass into a fuel gas mainly made of carbon monoxide, hydrogen, and methane. This fuel can produce heat, which helps dry the biosolids. The system can reduce the volume of biosolids by up to 95% cleanly and efficiently.

Fluidized Bed Gasifier

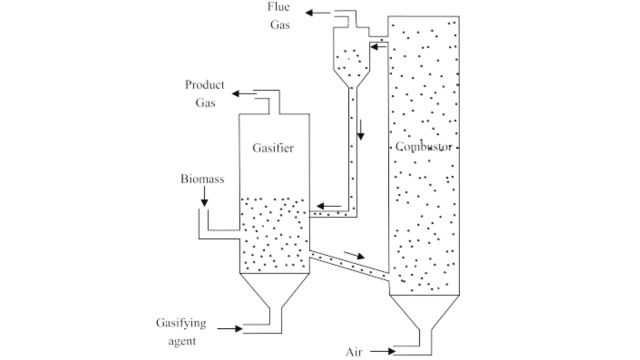

Fluidized bed gasifiers mix feedstocks and gases evenly, leading to higher production. In this process, gasification occurs in a hotbed of inert materials like sand or alumina, which is kept in motion by an upward gas flow. As the gas flow increases, the materials become “fluidized,” enhancing the reaction between the bed material and biomass. This results in a higher reaction rate compared to fixed bed gasification.

Fluidized bed systems can handle a wider range of biomass feedstocks and operate at larger scales, producing gas with higher energy content. However, they are more expensive and complex to manage.

Types of fluidized bed gasifiers

There are two main types of fluidized bed gasifiers:

- Bubbling fluidized bed

- Circulating fluidized bed (CFB)

Both types can operate at atmospheric or pressurized conditions. They offer better temperature distribution, and excellent heat and mass transfer rates. These systems can be scaled up for medium to large operations. However, bed materials and char can lead to higher concentrations of solid particles in the product gas, which need removal. Larger reactors can operate as CFB reactors, increasing the conversion of solids.

Operation of Fluidized Bed Gasifier

Fluidized-bed gasifiers keep feedstock particles suspended in an oxygen-rich gas, making the bed inside the gasifier behave like a fluid. These gasifiers mix new coal particles with those already undergoing gasification. Small coal particles (less than 6 mm) are used to keep the particles suspended. Coal enters from the side, while steam and oxidant enter from the bottom with enough speed to fluidize the bed.

This thorough mixing maintains a constant temperature in the reactor bed, which operates at a moderately high temperature to achieve a good carbon conversion rate (90-95%) and break down most tars, oils, and other liquid byproducts. However, the temperature is kept below the ash fusion point to prevent clumping and maintain fluidization. Therefore, fluidized-bed gasifiers are ideal for reactive coals, low-rank coals, and other fuels like biomass.

Characteristics of Fluidized Bed Gasifier

Fluidized-bed gasifiers vary in ash handling (dry or slagging) and char use efficiency. Based on fluidization and bed height, they can also be called circulating fluidized bed reactors or transport reactors.

Key characteristics:

- Flexible load and high heat transfer rates

- Can gasify diverse feedstocks

- Moderate oxidant and steam needs

- Uniform, moderately high-temperature

- Require extensive char recycling

Design and Development of Fluidized Bed Gasifier

Arvind Envisol has developed a fluidized bed gasifier system for thermal applications, providing heat in the range of 400,000-500,000 kcal/h. These gasification Plants include:

- Screw feeder for fuel feeding

- Fluidized bed reactor

- Distributor plate

- Coarse and fine cyclone separators

- Organic and fabric filters

- Regenerative blower

- Burner

Advantages of Fluidized Bed Gasifier

- Higher carbon conversion and thermal efficiency.

- More efficient than combustion systems with lower emissions.

- Better heat and mass transfer than conventional gasifiers.

- Multi-fuel flexibility for thermal and power applications.

- Converts non-homogeneous biomass waste to pure, homogenous fuel gas.

- Can produce electricity, ammonia, oil, methane, and hydrogen through integrated gasification combined cycles.

Disadvantages of Fluidized Bed Gasifier

- High initial cost and complex operation.

- Requires precise control of temperature and fluidization.

- Higher maintenance due to moving parts and abrasive materials.

- Potential for bed material loss and handling issues.

- Not suitable for all types of feedstocks, especially those with high ash content.

Frequently Asked Questions (FAQs)

What are fluidized bed gasifiers?

Fluidized bed gasifiers are devices that convert solid fuels into gas by mixing the fuel with hot air or gas, making it behave like a fluid for efficient and even chemical reactions.

What is the principle of a fluidized bed reactor?

A fluidized bed reactor works by blowing gas or liquid through solid particles, making them float and mix like a fluid. This improves heat transfer and chemical reaction efficiency.

What are the two types of fluidized bed reactors?

The two types of fluidized bed reactors are bubbling fluidized bed reactors, where particles mix gently, and circulating fluidized bed reactors, where particles circulate rapidly, enhancing mixing and reaction rates.

Leave a Reply