Table of Contents

Introduction

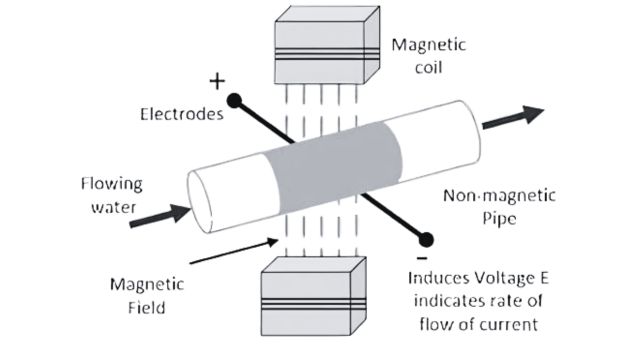

A magnetic flow meter, also known as a mag meter or electromagnetic flow meter, measures the flow of a fluid by using the voltage generated as the fluid moves through a magnetic field. When a magnetic field is applied across a pipe with fluid, it creates a voltage proportional to the fluid’s flow speed. This principle is based on electromagnetic induction. For this method to work, the fluid must be conductive, such as water-containing ions, and the pipe must have an insulating surface, like a rubber lining.

Electromagnetic Flow Meter

An electromagnetic flow meter measures the flow of liquid in a pipeline. It is specifically used for liquids that can conduct electricity, meaning they allow current to pass through them.

The flow meter works by placing a magnetic field in the path of the flowing liquid. As the liquid moves, it creates a voltage across the coils in the meter. This voltage is used to determine the flow rate of the liquid.

Construction of Electromagnetic Flow Meter

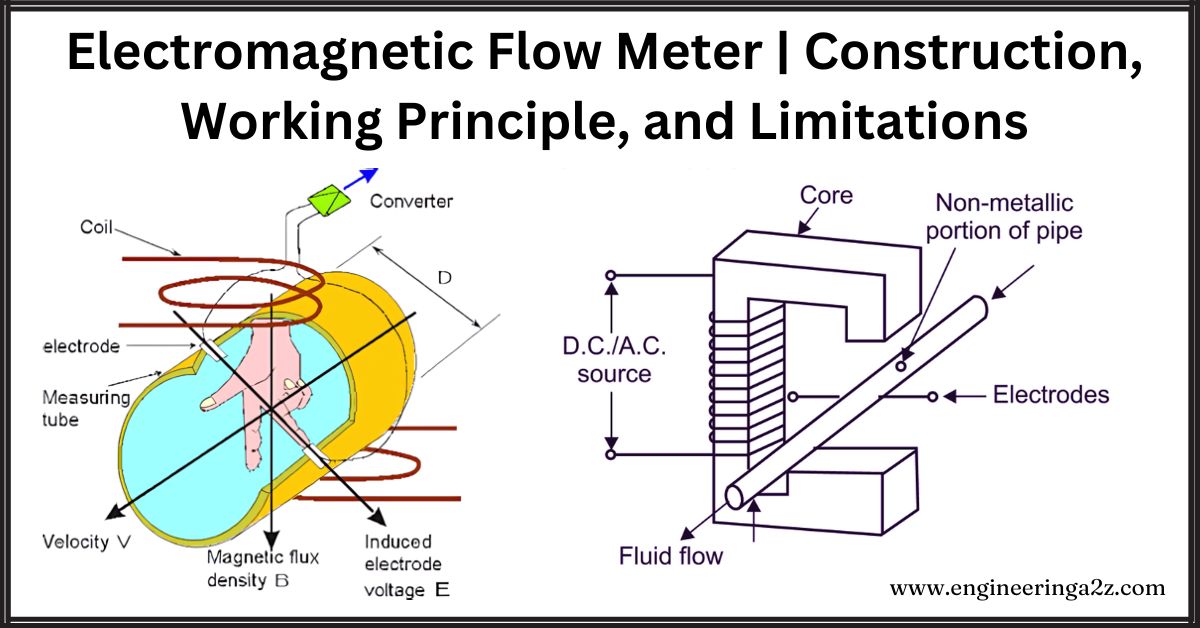

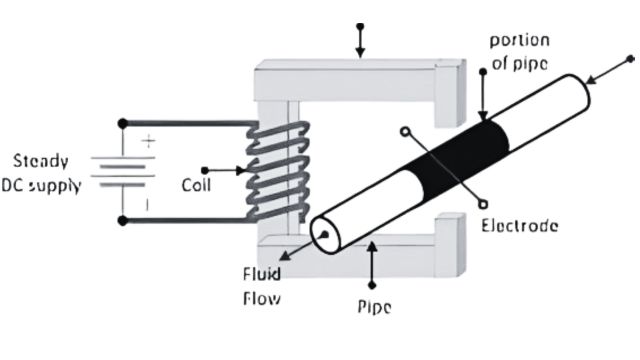

An electromagnetic flow meter consists of an electrically insulated pipe, usually made of fiber. Inside the pipe, there are electrodes placed opposite each other and magnetic coils are wrapped around the pipe to create a magnetic field. The insulated pipe carries the liquid whose flow rate needs to be measured.

When the liquid flows through the pipe, it acts like a moving conductor in a magnetic field. The magnetic coils around the pipe generate a magnetic field, and as the liquid moves, it induces a voltage across the electrodes. The amount of voltage generated depends on the speed of the liquid, the diameter of the pipe, and the strength of the magnetic field.

If the magnetic field stays constant, the voltage produced is directly proportional to the velocity of the liquid. This voltage is used to calculate the flow rate of the liquid.

Working Principle of Electromagnetic Flow Meter

An electromagnetic flow meter operates based on Faraday’s Law of electromagnetic induction. According to this law, when a conductive liquid flows through a magnetic field, it generates a voltage. The amount of voltage produced depends on the liquid’s speed, the length of the conductor, and the strength of the magnetic field.

In the flow meter, the magnetic field is created by coils mounted outside the pipe. As the liquid flows through the pipe, it acts as a conductor, causing voltage to be induced across the coils. The faster the liquid flows, the greater the voltage generated. This voltage is then used to measure the flow rate of the liquid.

Advantages of Electromagnetic Flow Meters

1. Highly Accurate:

- ±0.5% accuracy over a wide range of flows, better than the ±1-2% of ultrasonic meters.

- Crucial for accurate water-based solution measurements, reducing costs, and improving efficiency.

2. Cost-Effective:

- Accurate measurements prevent overcharging or under-delivery.

- Simple installation can retrofit existing systems without stopping the flow.

- No moving parts, resulting in low maintenance and operational costs.

3. Measure Bi-directional Flow:

- Can measure flow in both directions, unlike other meters that require two units for this function.

- Useful for complex industrial systems needing bi-directional flow monitoring.

Limitations of Electromagnetic Flow Meters

- Conductive Fluids Only: Cannot measure non-conductive fluids like gases, steam, or petroleum products.

- Resistance Requirement: The liquid’s resistance between electrodes must be less than 1% of the external circuit’s impedance.

- Expensive: These meters are costly.

- Volume Inclusion: Measures volume rate, including any suspended particles in the liquid.

- Installation Considerations: Must be installed with electrodes on the horizontal diameter to avoid air interference; zero checks require stopping the flow and possibly using a bypass.

Frequently Asked Questions (FAQs)

What are the types of Electromagnetic Flow Meters?

There are two main types of electromagnetic flow meters: Insertion Type and Full-Bore Type. Insertion types are installed into the pipe, while full-bore types fit around the entire pipe diameter.

What are the disadvantages of an Electromagnetic Flow Meter?

Electromagnetic flow meters can only measure conductive liquids, not non-conductive fluids like gas. Installation and setup are complex, requiring careful adherence to specifications and protection from magnetic fields and vibrations.

What is the application of Electromagnetic flow meters?

Electromagnetic flow meters are used to measure the flow of conductive liquids in water treatment, chemical processing, food and beverage production, pharmaceuticals, mining, and pulp and paper industries.

Leave a Reply