Table of Contents

Introduction

Gasification is a process that turns biomass or fossil fuels into gases like nitrogen (N2), carbon monoxide (CO), hydrogen (H2) and carbon dioxide (CO2). This happens by heating the material to high temperatures (over 700°C) without burning it, using controlled amounts of oxygen and steam. The resulting gas, called syngas or producer gas, can be used as fuel because it contains flammable H2 and CO2.

Biomass

Biomass is a renewable organic resource that includes crop residues (corn stalks or wheat straw), forest residues, special energy crops (like switchgrass or willow trees), organic municipal waste and animal waste. Biomass can be used to produce hydrogen and other byproducts through gasification.

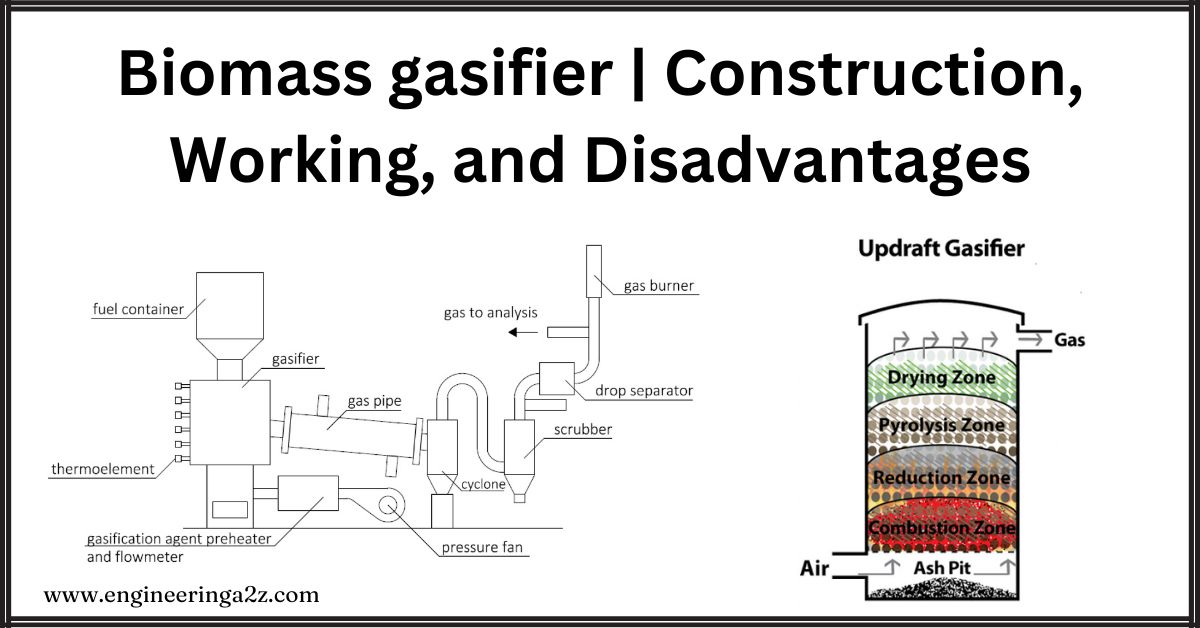

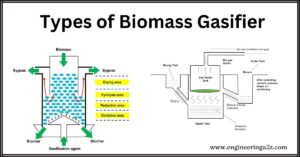

Construction of Biomass Gasification

The construction of a biomass gasification system typically includes the following components :

- Feedstock Hopper: A container that stores and feeds biomass materials like wood chips, agricultural residues or other organic waste into the gasifier.

- Gasifier Reactor: The core component where biomass is heated in the presence of a controlled amount of oxygen or steam. This reactor can be of different types, such as updraft, downdraft, cross-draft or fluidized bed.

- Air or Steam Supply: A system that provides the necessary air or steam to the gasifier to facilitate the gasification process. This is often regulated to maintain the correct conditions for efficient gasification.

- Cyclone Separator: A device that separates ash and solid particles from the produced gas. The gas flows through a cyclone chamber where particles are removed by centrifugal force.

- Cooling and Cleaning System: This system cools the hot gas and removes tar, particulates and other impurities. This can include scrubbers, filters and other purification devices.

- Gas Outlet: The cleaned and cooled gas is collected and directed to the gas outlet, where it can be used as fuel for engines, turbines or other applications.

- Ash Removal System: Ash generated during gasification is collected and removed from the reactor, often through an automated system to maintain continuous operation.

These components work together to efficiently convert biomass into syngas, which can then be used for various energy applications.

Working on Biomass Gasification

Gasification converts organic or fossil materials into gases at high temperatures (over 700°C) without burning them, using controlled amounts of oxygen and steam. This process produces carbon monoxide (CO), hydrogen (H2) and carbon dioxide (CO2). The CO reacts with water to create more CO2 and H2 in a water-gas shift reaction. Special membranes or adsorbers can then separate the hydrogen.

Example reaction:

C6H12O6 + O2 + H2O → CO + CO2 + H2 + other compounds

(Note: This reaction uses glucose to represent cellulose. Actual biomass is more complex, with cellulose being a key component.)

Water-gas shift reaction:

CO + H2O → CO2 + H2 (with a small amount of heat)

Pyrolysis is a type of gasification done without oxygen. Biomass is harder to gasify than coal and produces other hydrocarbons. These need an extra step with a catalyst to clean the gas mixture. Then, a shift reaction with steam converts CO to CO2 and the hydrogen is separated and purified.

Advantages of Biomass Gasification

- Converts Waste to Energy: Turns waste into electricity, hydrogen gas and biofuels, supporting a circular economy.

- Reduces Landfill Use: Less landfill space is needed, reducing groundwater pollution and related diseases.

- Versatile Feedstocks: Can process various feedstocks, useful in areas with stubble burning.

Disadvantages of Biomass Gasification

- Low Energy Output: Biomass has a higher moisture content and low heating value than coal, leading to less energy and variable output.

- Feedstock Availability: Difficulties in gathering and transporting local feedstock.

- Technical Issues: Formation of solid tar can clog equipment and pipelines, reducing system efficiency.

Frequently Asked Questions (FAQs)

What is the working principle of a gasifier?

A gasifier converts organic or fossil-based materials into gas by heating them at high temperatures with controlled oxygen, creating carbon monoxide, hydrogen, and carbon dioxide.

What are the applications of biomass gasifiers?

Biomass gasifiers are used to generate electricity, produce heat, create hydrogen, and make biofuels. They also help manage waste, reduce landfill use and support renewable energy and sustainable practices.

What is the classification of biomass gasifiers?

Biomass gasifiers are classified mainly into four types: updraft, downdraft, crossdraft and fluidized bed gasifiers. Each type differs in air intake direction, gas output and suitability for various feedstocks and applications.

Related Posts

- Pyrolysis | Basic Principles, Types and Uses

- Waste to Energy | Methods, Economic Impact and Future Trends

- Fluidized Bed Gasifier | Types, Operation, Design and Development

- Biomass Gasifier | Construction, Working, and Disadvantages

- Types of Biomass Gasifier

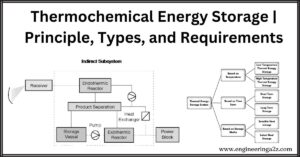

- Thermochemical Energy Storage | Principle, Types, and Requirements

Leave a Reply