Table of Contents

Biogas Plant

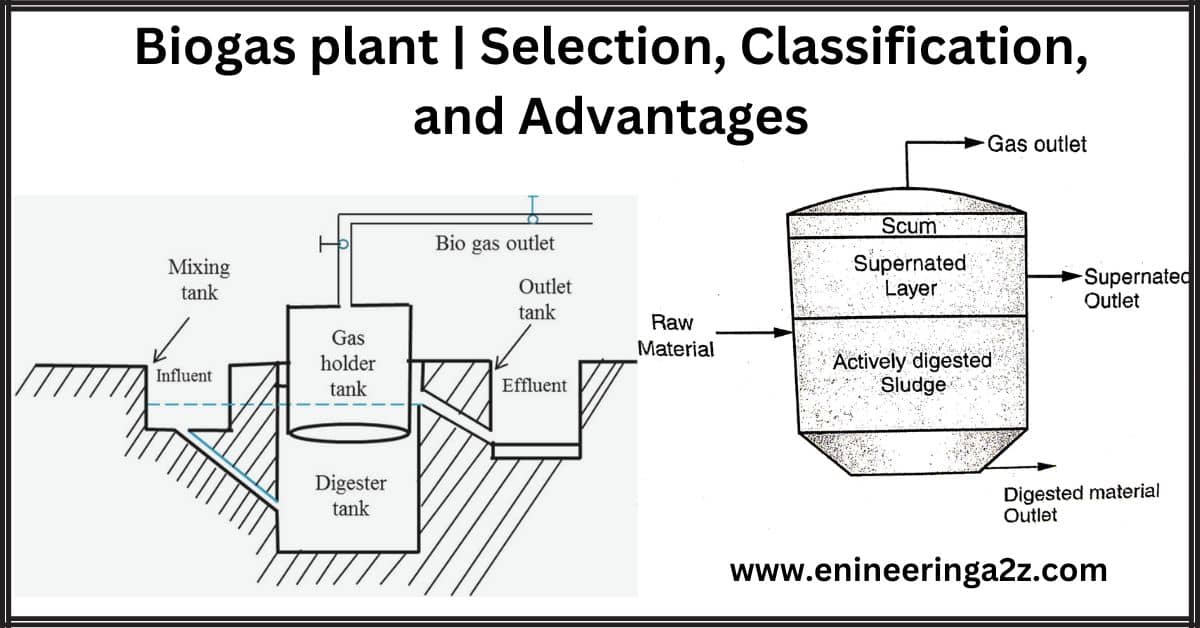

A biogas plant is a facility that converts organic waste into biogas through anaerobic digestion. It consists of an enclosed digester where microorganisms break down organic materials like agricultural waste, animal manure, or food waste in the absence of oxygen. This process produces biogas, primarily methane, and carbon dioxide.

Biogas can be used as a renewable energy source for heating, electricity generation, or transportation fuel. The leftover residue, called digestate, can be used as a nutrient-rich fertilizer. Biogas plants help mitigate greenhouse gas emissions, promote waste management, and provide energy security by utilizing local organic resources.

Selection of Biogas Plant

The main factors that influence the selection of a particular design or model for a biogas plan are as follows:

(i) Technical factors: These factors are the removal of sludge, the balance of bacteria, and construction material. Some slurry must be left for restarting the process after cleaning.

(ii) Climate factor: This retention time depends on ambient temperature.

(iii) Geographical factor: This decides the selection of vertical or horizontal biodigester

(iv) Economic: An ideal plant should be as low-cost as possible.

(v) Simple design: The design should be simple not only for construction but also for operation and maintenance.

(vi) Utilization of materials: The use of easily available local materials should be emphasized in the construction of a biogas plant.

(vii) Durability: The plant should have a long life.

(viii) Suitability for inputs: The design should be compatible with the different types of inputs that would be used.

Classification of Biogas Plant

Biogas plants are mainly classified as:

- Continuous and Batch type.

- The dome and the drum type.

- Different variations in the drum type.

1. Continuous and Batch Type

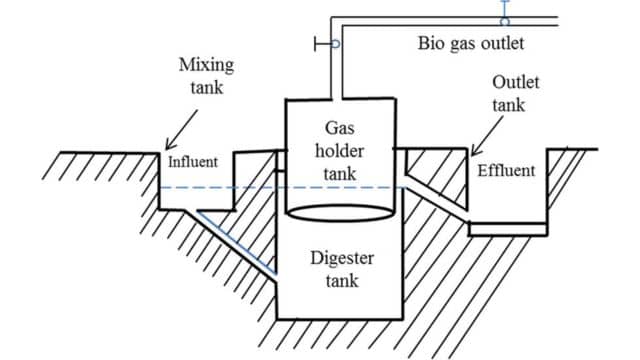

(a) Continuous Plant

There is a single digester in which raw materials are charged regularly and the process goes on without interruption except for repair and cleaning etc. In this case, the raw material is self-buffered (like cow dung) or otherwise thoroughly mixed with the digesting mass where dilution prevents souring and the biogas production is maintained. The continuous process may be completed in a single stage or separated into two stages.

(i) Single Stage process: The entire process of conversion of complex organic compounds into biogas is completed in a single chamber. This chamber is regularly fed with raw materials while the spent residue keeps moving out. Serious problems are encountered with agricultural residues when fermented in a single-stage continuous process.

(ii) Double Stage process: The acidogenic stage and methanogenic stage are physically separated into two chambers. Thus, the first stage of acid production is carried out in a separate chamber and only the diluted acids are fed into the second chamber where bio methanation takes place and the biogas can be collected from the second chamber.

The main features of the continuous plant are that:

(i) It will produce gas continuously.

(ii) It requires small digestion chambers.

(iii) It needs a lesser period for digestion.

(iv) It has fewer problems compared to batch type and it is easier to operate.

(b) The Batch Plant

The feeding is between intervals, the plant is emptied once the process of digestion is complete. In this type, a battery of digesters is charged along with lime, urea, etc., and allowed to produce gas for 40-50 days. These are charged and emptied one by one in a synchronous manner which maintains a regular supply of gas through a common gas holder.

Sometimes the freshly charged digester is aerated for a few days after which it is closed to the atmosphere. The biogas supply may be utilized after 8-10 days. Obviously, such a plant would be expensive to install and unless operated on large scale it would not be economical. Their installation and operation are capital and labor-intensive.

The main features of the batch plant are:

(i) The gas production in it, is intermittent, depending upon the cleaning of the digester.

(ii) It needs several digesters or chambers for continuous gas production, these are fed alternatively.

(iii) Batch plants are good for long fibrous materials.

(iv) This plant needs the addition of fermented slurry to start the digestion process. There may be a direct change to the acid phase in the absence of the fermented slurry, which affects the formation of methane.

(v) This plant is expensive and has problems comparatively, the continuous plant will have fewer problems and will be easy to operate.

2. The Dome and the Drum Type

The biogas plant is of mainly two types:

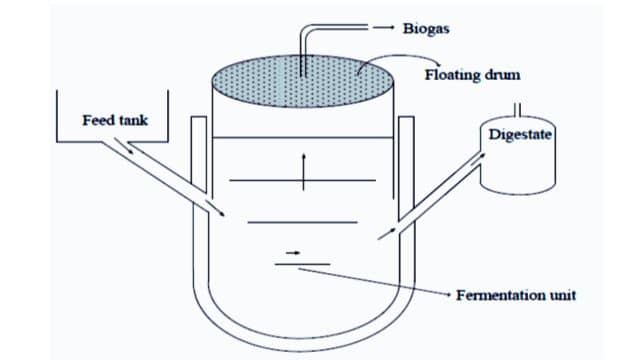

(a) Floating drum digester

Floating drum digesters are biogas plants constructed above ground using a steel drum. They are cheaper and easier to maintain compared to underground digesters. The digester chamber is made of brick masonry, and a steel drum collects the biogas. The drum moves up and down on a guide pipe to maintain constant pressure. However, these plants are now outdated due to higher costs and maintenance compared to fixed dome designs.

(b) Fixed Dome Digester

The fixed dome digester is an underground biogas plant with a brick masonry fermentation chamber and a dome for gas storage. This design combines the fermentation chamber and gas holder, eliminating the need for a costly steel drum. The fixed dome design has a longer lifespan (20 to 50 years) compared to floating drum plants. It maintains a slightly higher temperature and may include a displacement chamber to accommodate excess slurry caused by gas pressure in the dome. It is fed daily and adjusts to changes in gas pressure and volume.

Advantages of Biogas

There are several advantages of biogas plants. Here are five key advantages:

- Renewable Energy: Biogas plants produce renewable energy in the form of biogas. Biogas is a sustainable alternative to fossil fuels, and its production helps reduce dependence on non-renewable energy sources.

- Waste Management: Biogas plants effectively manage organic waste materials such as agricultural residues, animal manure, and food waste. Instead of being disposed of in landfills, these wastes are converted into biogas, reducing environmental pollution and odors associated with waste decomposition.

- Greenhouse Gas Reduction: Biogas production through anaerobic digestion prevents the release of methane, a potent greenhouse gas, into the atmosphere. Methane emissions from organic waste are captured and utilized as biogas, reducing the overall carbon footprint and mitigating climate change.

- Fertilizer Production: The byproduct of anaerobic digestion, called digestate, is a nutrient-rich fertilizer. It can enhance soil fertility, improve crop yields, and reduce the need for synthetic fertilizers, promoting sustainable agriculture practices.

- Energy Independence and Local Economy: Biogas plants utilize locally available organic resources, fostering energy independence and reducing dependence on imported fuels. This localized approach supports local economies, creates job opportunities, and contributes to sustainable rural development.

Overall, biogas plants offer multiple benefits, including renewable energy generation, waste management, greenhouse gas reduction, fertilizer production, and supporting local economies, making them a valuable and sustainable solution for energy and waste management needs.

Disadvantages of Biogas

Here are three disadvantages of biogas plants summarized in 100 words:

- High initial investment costs can be a barrier for individuals or organizations with limited financial resources, making it challenging to establish a biogas plant.

- Feedstock availability and quality can fluctuate, depending on seasonal variations and waste collection infrastructure, potentially affecting the efficiency and performance of the plant.

- Operating a biogas plant requires specialized technical expertise and maintenance. Inadequate knowledge or insufficient maintenance can result in reduced biogas production, decreased efficiency, and increased operational costs. However, these challenges can often be addressed through proper planning, support, technology advancements, and knowledge sharing among stakeholders.

Frequently Asked Questions (FAQs)

What is a biogas plant?

A biogas plant, also known as a biogas digester or anaerobic digestion facility, is a specialized facility that converts organic waste materials into biogas through a process called anaerobic digestion. It is a renewable energy production system that utilizes natural biological processes to generate energy in the form of biogas.

What is biomass?

Biomass is renewable organic matter generated by plants in the process of photosynthesis.

What is bioenergy?

Bioenergy is the stored chemical energy derived from materials such as wood, rice, husk, straw or animal wastes, etc.

What are the constituents of biomass materials?

The main constituents of biomass material are:

i) Cellulose

ii) Hemi cellulose

iii) Lignin

iv) Ash

v) Mineral matters

Read Also:

- Advantages | Disadvantages and Applications of Electric Power

- DIAC | Construction | Working and V-I Characteristics

- Electric Traction | Speed-Time Curve

- Difference between HVDC and HVAC

- Solar Cookers | Working Principle, Construction, and Applications

Leave a Reply