Table of Contents

Biomass Gasifier

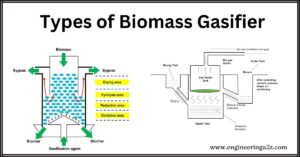

Biomass gasifiers convert organic materials into gas for energy production. The main types are updraft and downdraft gasifiers. Updraft gasifiers draw air in from the bottom and expel gas from the top. They are simple and efficient but produce tar, requiring careful handling. Downdraft gasifiers, on the other hand, take in air from the top and release gas from the bottom, producing cleaner gas with minimal tar, making them suitable for engine use. However, they need high-quality fuel and struggle with fluffy or high-ash materials. Both types play crucial roles in converting waste into energy, each with its advantages and challenges.

Types of Biomass Gasifier

- Updraught or counter-current gasifier

- Downdraught or co-current gasifier

- Cross-draught gasifier

- Fluidized bed gasifier

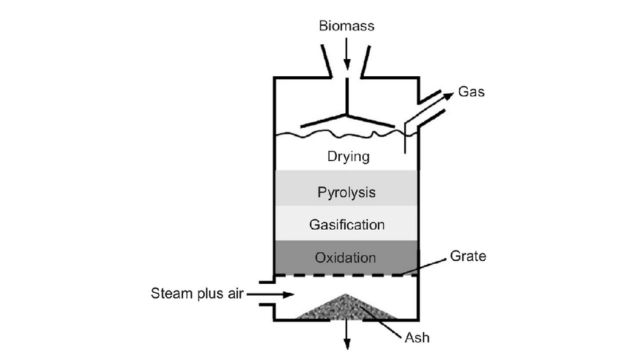

1. Updraught or Counter-Current Gasifier

- In an updraft gasifier, the biomass is fed from the top, and the gasifying agent (air, oxygen, or steam) enters from the bottom.

- The gases move upward through the biomass and the resulting syngas exit from the top.

- This type is efficient in using heat but can produce more tar in the syngas.

- Heating and Pyrolysis: In the upper part, the feedstock is heated and broken down by heat from below.

- Tar and Ash Handling: Tars and volatiles move with the gas; ashes are removed from the bottom.

Advantages of Updraught or Counter-Current Gasifier

- Simple Design: Easy to construct and operate.

- High Efficiency: Good charcoal burn-out and low gas exit temperatures.

- Versatile Feedstock: Can use various materials like sawdust and cereal hulls.

Drawbacks of Updraught or Counter-Current Gasifier

- Channeling Risk: This can lead to dangerous oxygen leaks and explosions.

- Moving Grates Needed: Requires automatic moving grates to operate effectively.

- Tar Disposal: Produces tar-containing condensates that need to be managed, though less of an issue if the gas is used for direct heating (tars are burned off).

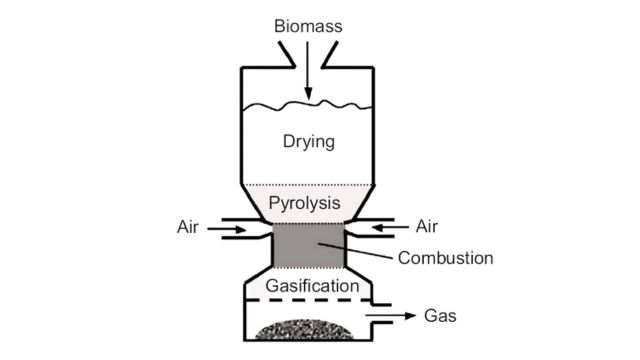

2. Downdraught or Co-Current Gasifier

- In a downdraft gasifier, both the biomass and the gasifying agent enter from the top.

- The gases move downward through the biomass and the syngas exit from the bottom.

- This type produces cleaner syngas with less tar, making it suitable for small-scale applications.

- Tar Breakdown: The hotter the zone and the longer the tar stays in it, the more complete the breakdown of tars.

Advantages of Downdraught or Co-Current Gasifier

- Tar-Free Gas: Can produce gas with very low tar content, suitable for engines.

- Environmental Benefit: Produces less tar, leading to fewer environmental concerns compared to updraft gasifiers.

Drawbacks of Downdraught or Co-Current Gasifier

- Limited Fuel Types: Cannot handle unprocessed, low-density fuels well; these need to be pelletized or briquette first.

- Ash Problems: Struggles more with high ash content fuels, which can cause slagging.

- Lower Efficiency: Less efficient than updraft gasifiers due to the lack of internal heat exchange and lower heating value of the gas.

- Power Limit: Not practical for power ranges above 350 kW due to the need to maintain high, uniform temperatures.

3. Cross-Draught Gasifier

High Temperatures: Designed for charcoal, these gasifiers can reach over 1500°C. The charcoal itself insulates against these high temperatures.

Advantages of Cross-Draught Gasifier

- Small Scale: Economically viable for installations under 10 kW.

- Simple Cleaning: Uses a basic cleaning system (cyclone and hot filter), suitable for small engines.

Disadvantages of Cross-Draught Gasifier

- Tar Conversion: Limited ability to convert tar, requiring high-quality, low-volatile charcoal.

- Charcoal Quality: Due to variable charcoal quality, some gasifiers use the downdraft method to help break down tars.

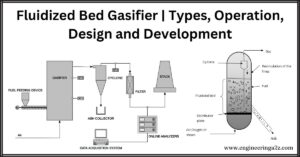

4. Fluidized Bed Gasifier

Design OF Fluidized Bed Gasifier

- Air Flow: Air blows through a bed of solid particles to keep them suspended.

- Heating: The bed is heated externally; fuel is added once the temperature is high enough.

- Mixing and Pyrolysis: Fuel mixes with the bed material and heats quickly, leading to rapid pyrolysis and gas production.

- Cyclone: An internal cyclone minimizes char blow-out; ash is removed from the gas stream.

Advantages Of Fluidized Bed Gasifier

- Flexible Feedstock: Can handle various materials (e.g., rice husks, sawdust) without pre-processing.

- Temperature Control: Easy to control, keeping temperatures below the ash melting point.

Drawbacks of Fluidized Bed Gasifier

- High Tar Content: Produces gas with high tar content (up to 500 mg/m³).

- Incomplete Carbon Burn-Out: Does not completely burn carbon.

- Load Changes: Poor response to load changes, requiring complex control equipment.

- Size Limitation: Not practical for minimal applications; typically used for over 500 kW.

Frequently Asked Questions (FAQs)

What is an upward and downward gasifier?

An updraft gasifier takes air from the bottom and releases gas at the top, producing more tar. A downdraft gasifier takes air from the top and releases gas at the bottom, producing cleaner gas.

What are the uses of biomass gasifiers?

Biomass gasifiers convert organic materials into gas, which can be used to produce electricity, heat, hydrogen, and biofuels. They also help reduce landfill waste and support sustainable energy practices.

Leave a Reply