Table of Contents

Introduction

A microsensor is a minuscule device built to sense and measure specific physical properties like temperature, pressure, light, or chemicals. Imagine a tiny gadget that acts as a super-sensitive detective, detecting even the smallest changes in its environment. These sensors are made using microtechnology, crafting them on a microscopic scale. Due to their small size, they can be integrated into numerous devices and systems, from smartphones and wearables to industrial machinery and medical instruments. Microsensors work by converting physical input (like light or temperature) into electrical signals that can be processed and used for various purposes, such as monitoring, control, or data collection. Their miniature size, precision, and ability to gather valuable information make them essential components in modern technology, enhancing functionalities and enabling smarter and more efficient devices.

Working Principle of Microsensors

Microsensors operate on the fundamental principle of converting a physical change or stimulus into an electrical signal, facilitating the detection and measurement of specific parameters in a miniaturized form. These sensors are crucial components in various fields due to their ability to detect and respond to changes in their environment at a microscopic scale.

The working principle of a microsensor depends on its specific type and the parameter it is designed to measure. However, a common element among most microsensors involves a transduction mechanism where the conversion of the physical quantity into an electrical signal occurs.

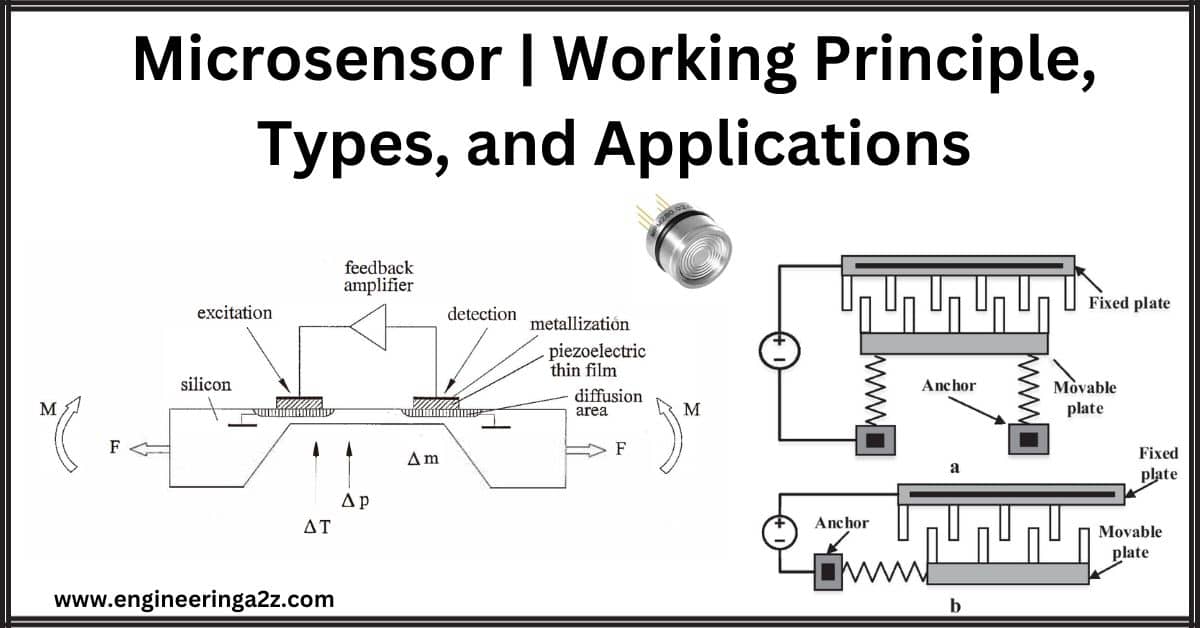

For instance, in a micro-pressure sensor, a change in pressure deforms a tiny diaphragm or structure within the sensor. This deformation leads to alterations in electrical properties such as capacitance, resistance, or voltage. These changes are then measured and converted into an electrical signal proportional to the applied pressure.

Similarly, micro temperature sensors rely on materials whose electrical properties change with temperature. For instance, the resistance of a material might increase or decrease with temperature variations. By measuring this change in resistance, the temperature can be accurately determined.

Microsensors might also utilize piezoelectric materials that generate an electric charge when subjected to mechanical stress or pressure. This principle is employed in sensors like accelerometers, where the force or acceleration experienced results in the generation of an electrical signal.

Another common principle involves chemical reactions. In microchemical sensors, specific materials or coatings react with target chemicals or gases. This reaction alters the electrical properties of the sensor, enabling the detection and quantification of the chemical substance.

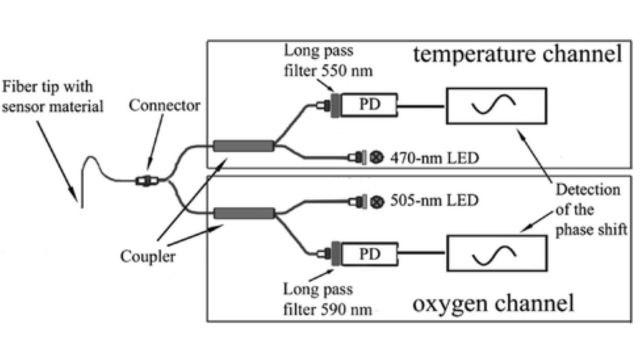

The advancements in microengineering have enabled the integration of mechanical, electrical, and sometimes optical components within these tiny sensors. These integrated systems may include microactuators, signal processing circuits, or even wireless communication modules, allowing for autonomous operation and enhanced functionality.

Overall, microsensors revolutionize sensing technology by combining miniaturization, accuracy, and versatility, enabling their widespread use across industries such as healthcare, automotive, environmental monitoring, and consumer electronics. Their ability to efficiently detect and measure various parameters at a miniature scale continues to drive innovation and technological advancements.

Types of Microsensor

Here’s an overview of the main types of microsensors:

- Nanosensors: These are ultra-small sensors that detect changes in physical quantities at a nanometer scale. They’re used in medicine and water quality monitoring to detect nanoparticles and monitor things like temperature and chemicals.

- Biochips or Bio-Microarray Systems: They come in three types—DNA, protein, and microfluidic chips, also known as Lab-on-a-chip. These tiny systems help in genetic and protein analysis, all packed into a small chip.

- Micro-Electro-Mechanical Systems (MEMS): These are chip-based systems containing sensors based on capacitive plates. They’re smart assemblies that miniaturize sensors, incorporating actuators and electronic circuits for signal processing. MEMS have greatly influenced sensor miniaturization and their applications due to advancements in the semiconductor industry.

Applications of Microsensors

- Healthcare: They’re in devices like glucose monitors and fitness trackers.

- Cars: Used for engine control, airbags, and brakes in vehicles.

- Environment: Measures temperature, humidity, and air quality.

- Industry: Monitors pH, temperature, and pressure in manufacturing.

- Tech: In smartphones, laptops, and gaming devices.

- Aerospace: Helps monitor planes for safety and navigation.

Advantages of microsensors

- Miniaturization: Their small size enables integration into compact devices and systems, making them ideal for portable applications and integration into smaller spaces.

- Enhanced Sensitivity: Microsensors can detect minute changes in physical parameters, providing high sensitivity and accuracy in measurement.

- Low Power Consumption: They often require minimal power to operate, making them suitable for energy-efficient devices and prolonging battery life in portable electronics.

- Fast Response Time: These sensors typically exhibit rapid response times, allowing for real-time monitoring and quick detection of changes in the environment.

- Versatility: They can measure various parameters such as temperature, pressure, chemical composition, motion, and more, making them adaptable to diverse applications across industries.

Disadvantages of microsensors

- Sensitivity to Environmental Factors: Microsensors can be sensitive to environmental conditions such as temperature variations, humidity, and electromagnetic interference, which might affect their accuracy.

- Limited Detection Range: Some microsensors might have a limited range of detection compared to larger sensors, restricting their use in certain applications requiring wider measurement ranges.

- Calibration and Maintenance: They might require frequent calibration and maintenance to ensure accurate and reliable measurements, especially in critical applications.

Frequently Asked Questions (FAQs)

What is a Microsensor?

A microsensor is a tiny device that detects and measures change in physical properties, converting them into electrical signals, crucial for various applications in miniature-scale technology.

What is the principle of micro sensor?

Microsensors operate on the principle of converting physical changes (like temperature, pressure, or chemical presence) into electrical signals, enabling measurement and detection in miniature-scale technology.

What are the classification of microsensors?

Microsensors are classified into nanosensors (ultra-small sensors detecting at the nanoscale), biochips (DNA, protein, microfluidic), and MEMS (incorporating mechanical, and electrical elements for sensing at miniature scales).

What are the 4 main types of sensors?

The four main types of sensors are:

1. Temperature Sensors: Measure temperature variations.

2. Pressure Sensors: Detect changes in pressure levels.

3. Proximity Sensors: Detect nearby objects without physical contact.

4. Motion Sensors: Detect movement or changes in position.

Read Also:

- Strain Gauge | Working | Types | Applications and Advantages

- Capacitive Transducer | Working | Advantages | Disadvantages and Uses

- LVDT | Construction | Principle | Advantages and Applications

- Power Quality | Sources Of Pollution, Need, and Effects

Leave a Reply