Table of Contents

Vortex Flow Meter

Vortex Flow Meter is a device used to measure the flow of liquids by harnessing the natural formation of vortices (or eddies) when liquid flows around a blunt object. The speed at which these vortices form is directly tied to the flow rate of the liquid.

One of the key advantages of vortex flow meters is that they have no moving parts, which means they experience less wear and tear. This makes them perfect for environments where moving parts could cause problems. They are available in various materials like industrial-grade metal, brass, or plastic, and they are also quite resilient, meaning they aren’t easily affected by changes in the process conditions.

Design of Vortex Flow Meter

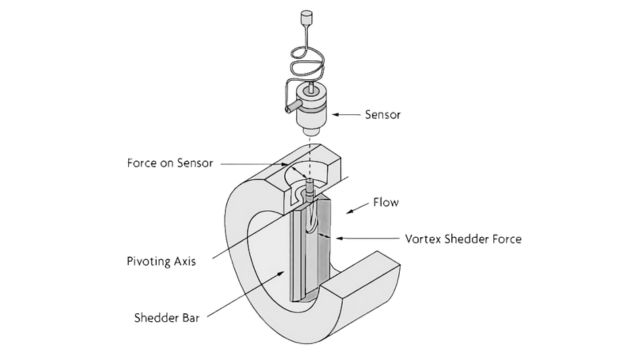

Vortex flow meter is typically made from durable materials like stainless steel or Hastelloy. It consists of three main parts: a bluff body, a vortex sensor, and transmitter electronics. The bluff body, which can be square, rectangular, or another shape, creates swirling vortices as the fluid flows around it. The sensors, often piezoelectric or capacitance types, detect these vortices and convert them into a low-voltage signal that corresponds to the frequency of the vortices.

Vortex meters are available in various sizes, usually ranging from ½ to 12 inches, and can be either flange-mounted or wafer-style. Wafer meters are more affordable, while flanged meters are typically used for handling hazardous or high-temperature fluids. The sensors can be located inside or outside the meter, with external sensors being preferable for harsh conditions. The electronic housing is designed to be weatherproof and may also include extra features, such as a flow-rate indicator.

Working Principle of Vortex Flow Meter

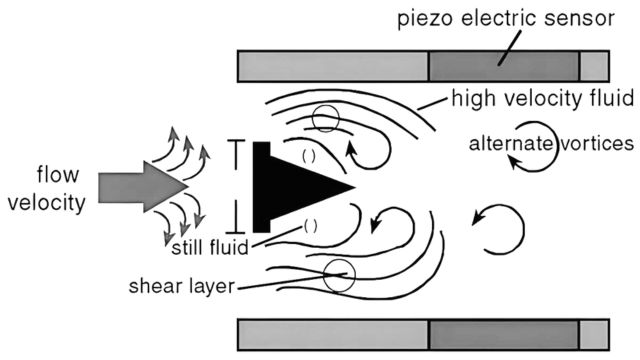

Vortex flow meters measure the flow of liquids, gases, and steam by detecting the frequency of swirling patterns, called vortices, that form when fluid moves around a fixed object known as a “bluff body” or “shedder bar.” The speed at which these vortices form is directly related to the fluid’s velocity.

These meters work best above a certain flow speed, called the “cut-off” point. If the flow is too slow or there is back-flow, the meter might not provide a reading, or it could give an inaccurate one.

Like orifice meters, vortex meters can cause a drop in pressure as the fluid passes through which can sometimes lead to issues like cavitation—especially with liquids that are close to their boiling point. Cavitation can damage the meter over time.

To ensure accurate readings, particularly in larger meters, vortex meters use digital multipliers to amplify the frequency signal from the vortices.

Accuracy and Rangeability of Vortex Flow Meter

Vortex flow meters are used to measure flow rates, but their accuracy can be influenced by the fluid’s viscosity and the flow conditions. As the viscosity of the fluid increases, the meter’s ability to measure a wide range of flows decreases, typically being effective up to 30 centipoises. For gases and steam, these meters can measure over a 20:1 range, while for low-viscosity liquids, the range is usually over 10:1.

The accuracy of vortex meters is generally reliable at high flow rates but tends to decrease at lower flow rates. When the Reynolds number is high (over 30,000) the accuracy is typically within 0.5-1%. However, at lower Reynolds numbers (below 10,000) the error can increase significantly, up to 10%.

Vortex meters also have a “cut-off” point, below which they don’t provide accurate readings and instead output zero. This cut-off can be problematic when measuring very low flow rates, especially during start-up or shutdown phases.

Advantages of Vortex Flow Meter

- Low Pressure Loss: The pressure loss is minimal, about 1/4 to 1/2 that of throttling differential pressure flowmeters.

- Accurate Output: The output pulse signal is directly proportional to the flow rate with no zero drift

- Reliable and Long-lasting: The measuring elements are simple, reliable, and have a long lifespan.

- Wide Measurement Range: A well-sized vortex flow meter can measure up to 20:1.

Disadvantages of Vortex Flow

- Vibration Sensitivity:

- External Vibration: Vortex flow meters can be sensitive to external vibrations, which may cause errors or prevent them from working properly.

- High-Speed Fluid Impact: When fluids move at high speeds, especially in large pipes, it can reduce the meter’s accuracy.

- Dirty Media:

- Susceptible to Dirt: The vortex generator in the meter can become dirty or clogged, which can negatively impact its accuracy.

- Straight Pipe Requirements:

- High Requirements: For accurate measurements, vortex flow meters need long sections of straight pipe—typically 40 times the pipe diameter (40D) upstream and 20 times the diameter (20D) downstream.

- Temperature Limitations:

- Limited Temperature Range: These meters can generally measure media flow up to 300°C, so they have a limited temperature range.

Frequently Asked Questions (FAQs)

What is the meaning of Vortex?

A vortex is a spinning or swirling motion of a fluid, like water or air, around a central point. It looks like a whirlpool or tornado and occurs naturally.

What media can vortex flow meters measure?

Vortex flow meters can measure liquids, gases, and steam. They detect flow by analyzing vortices created when the fluid flows past an obstruction, making them versatile for various applications.

What are vortex flow meters?

Vortex flow meters measure flow rates by detecting vortices formed as fluid flows around an obstruction. They work for liquids, gases, and steam, offering accurate and reliable measurements.

Leave a Reply