Table of Contents

An electronic flow meter measures the flow of liquids and gases in industries. Common types include electromagnetic, vortex and ultrasonic flow meters. They can measure things like water, gasoline, and air. These meters turn the flow into electronic signals, such as pulse or 4-20mA signals. They are reliable and accurate since they don’t have moving parts and use advanced electronics.

Electronic Flow Meter

A flow meter measures the amount of gas or liquid flowing through it. Depending on the industry, they can be called different names like flow indicators, liquid meters or flow sensors.

Electronic flow meters for measuring liquid flow include electromagnetic, vortex and ultrasonic flow meters.

Working Principle of Electronic Flow Meter

An electronic flow meter measures how much liquid or gas is moving through it. Here’s how it works:

- Sensors Detect Flow: The meter has sensors that measure the fluid passing through.

- Convert to Electrical Signals: These sensors change the flow into electrical signals

- Process the Signals: The meter’s electronics use these signals to calculate the flow rate.

- Display the Information: The flow rate and total flow are shown on a digital screen.

- Send Output Signals: The meter can also send this data to other systems for monitoring or control.

These meters are accurate, reliable, and easy to maintain because they have no moving parts.

Types of Electronic Flow Meter

Electronic flow meters can be roughly divided into three categories based on their technology.

- Electromagnetic flow meter

- Vortex flow meter

- Ultrasonic flow meter.

1. Electromagnetic Flow Meter

Electromagnetic flow meters measure the flow of fluids like water by using Faraday’s principle. Here’s an explanation of how they work:

- Setup: The meter has a pipe with insulation, magnetic coils that create a magnetic field and electrodes inside the pipe.

- Flow Measurement: As the fluid flows through the magnetic field in the pipe, it generates a small voltage across the electrodes.

- Voltage and Flow Rate: The amount of voltage produced depends on how fast the fluid is moving. The faster the flow, the higher the voltage. The meter uses this voltage to calculate the flow rate.

In short the meter converts the speed of the fluid into a measurable voltage to figure out how much fluid is flowing through the pipe.

2. Vortex Flow Meter

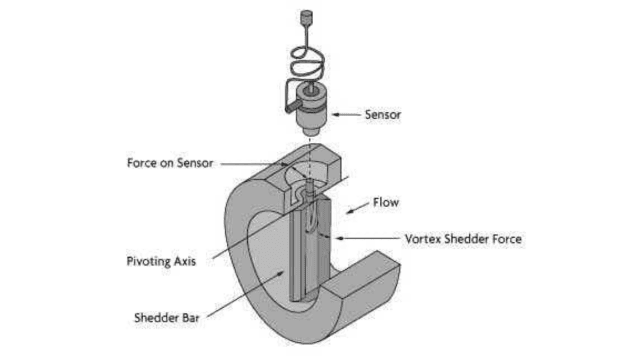

Vortex flow meters measure fluid flow by detecting swirling patterns called vortices that form when fluid moves around a blunt object placed in its path.

- Setup: The flow meter contains a blunt object inside the pipe. As fluid flows past this object, it creates swirling vortices.

- Vortex Detection: Sensors detect the pressure changes caused by these vortices. The frequency at which the vortices form is used to determine the fluid’s velocity.

- Flow Calculation: The fluid’s velocity is calculated using the formula V = f × h / S, where 𝑓 is the vortex frequency, ℎ is the width of the blunt object, and 𝑆 is the Strouhal number which remains fairly constant for various flow rates.

- Volumetric Flow Rate: The total flow rate is then calculated by dividing the vortex frequency by a calibration factor K, using the formula Q = f / K.

In simple terms, this meter uses the swirling patterns in the fluid to measure how fast and how much fluid is flowing through the pipe.

3. Ultrasonic Flow Meter

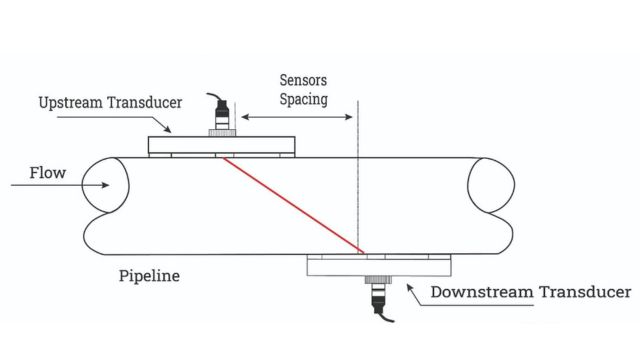

Ultrasonic flow meters measure fluid speed using high-frequency sound waves. They send sound waves through the fluid and analyze how the flow affects the waves. This helps determine how fast the fluid is moving.

There are two types: Doppler meters, which measure frequency changes and transit time meters, which measure travel time differences.

Advantages of Electronic Flow

Electronic flow meters use advanced technology to measure the flow of liquids or gases and they are widely used in different industries to monitor and control fluid flow.

- Energy Efficiency: By providing precise flow measurements, they help save energy by preventing the overuse or underuse of fluids.

- High Accuracy: These meters are more accurate than traditional mechanical ones, with an error margin of around 0.5%, making them ideal for precise measurements.

- Digital Display: Instead of a pointer, electronic flow meters have digital displays that show important details like flow rate, total flow, pressure, and temperature. You can also adjust the units to fit your needs.

- Reliability: With no moving parts, they are simple to install, maintain, and operate, with fewer chances of errors.

- Corrosion Resistance: The parts are made from materials that resist corrosion, making them perfect for industries like chemicals, pharmaceuticals, and food.

- Easy Maintenance: They are easy to take apart for repairs and need less frequent maintenance, which helps lower operating costs.

- Stable Output: Some models include temperature compensation, ensuring the signals remain consistent and accurate.

- Versatility: These meters can measure both liquids and gases and they can adapt to different types of fluids using various sensors.

Frequently Asked Questions (FAQs)

What is the unit of the flow meter?

The unit used by a flow meter depends on the type of fluid being measured. For liquids, it’s often measured in litres per second (L/s) or gallons per minute (GPM). For gases, it’s usually measured in cubic meters per hour (m³/h).

What are the three major methods of flow meters?

The three major methods of flow meters are:

1. Differential Pressure: The pressure difference across an obstruction measures flow.

2. Positive Displacement: Measures flow by capturing and releasing fluid in fixed volumes.

3. Velocity: Measures flow based on the speed of fluid movement, using methods like electromagnetic, vortex, and ultrasonic sensors.What is the working principle of in line flow meter?

The working principle of an in-line flow meter involves placing the meter directly in the fluid’s path. It measures the flow rate by detecting the fluid’s velocity, pressure, or volume as it passes through the meter.

Leave a Reply